BackPurging Stainless Steel

- HOME

- Tig Welding Stainless

- Tig Welding Stainless Steel

- Backpurging Stainless

Backpurging Stainless Pipe and Tube: Tips and Tools

When TIG welding stainless pipe and tube, protecting the inside of the weld from oxidation is just as important as the external appearance. That’s where backpurging comes in. This article breaks down practical methods and tools for effective backpurging to get clean, corrosion-resistant root passes every time.

Why Backpurging Is Necessary

Without backpurge, the inside of a stainless weld will oxidize and form a rough, dark gray or black crust. This "sugaring" weakens corrosion resistance and often fails inspection, especially in sanitary or food-grade applications.

Backpurging fills the inside of the pipe or tube with inert argon gas to displace oxygen during welding, keeping the root pass shiny and clean.

Basic Backpurge Setup

To get started:

- Seal both ends of the pipe or tubing

- Insert a second argon line for purge gas

- Vent the system with a small weep hole or vent at the top

Tools for Backpurging

- Purge Plugs or Dams – Silicone or rubber plugs seal off the ends and have ports for gas inlet and outlet

- Foil Tape & Cardboard – Budget-friendly solution for sealing short runs

- Purge Chambers or Inflatable Bladders – Great for large diameter or high-spec applications

- purge analyzer is recommended but not always required

Recommended Purge Procedure

- Seal Ends: Use purge plugs or tape

- Insert Argon Line: Flow 100% argon into the cavity

- Purge Time: Allow gas to fill the space before starting (time needed depends on volume)

- Vent Properly: Let oxygen escape from the top

- Weld: Maintain flow during and after welding for 20–30 seconds

Purge Flow Rates

- 1/4" to 2" tubing: 5–15 CFH

- 3" and up: 15–30 CFH

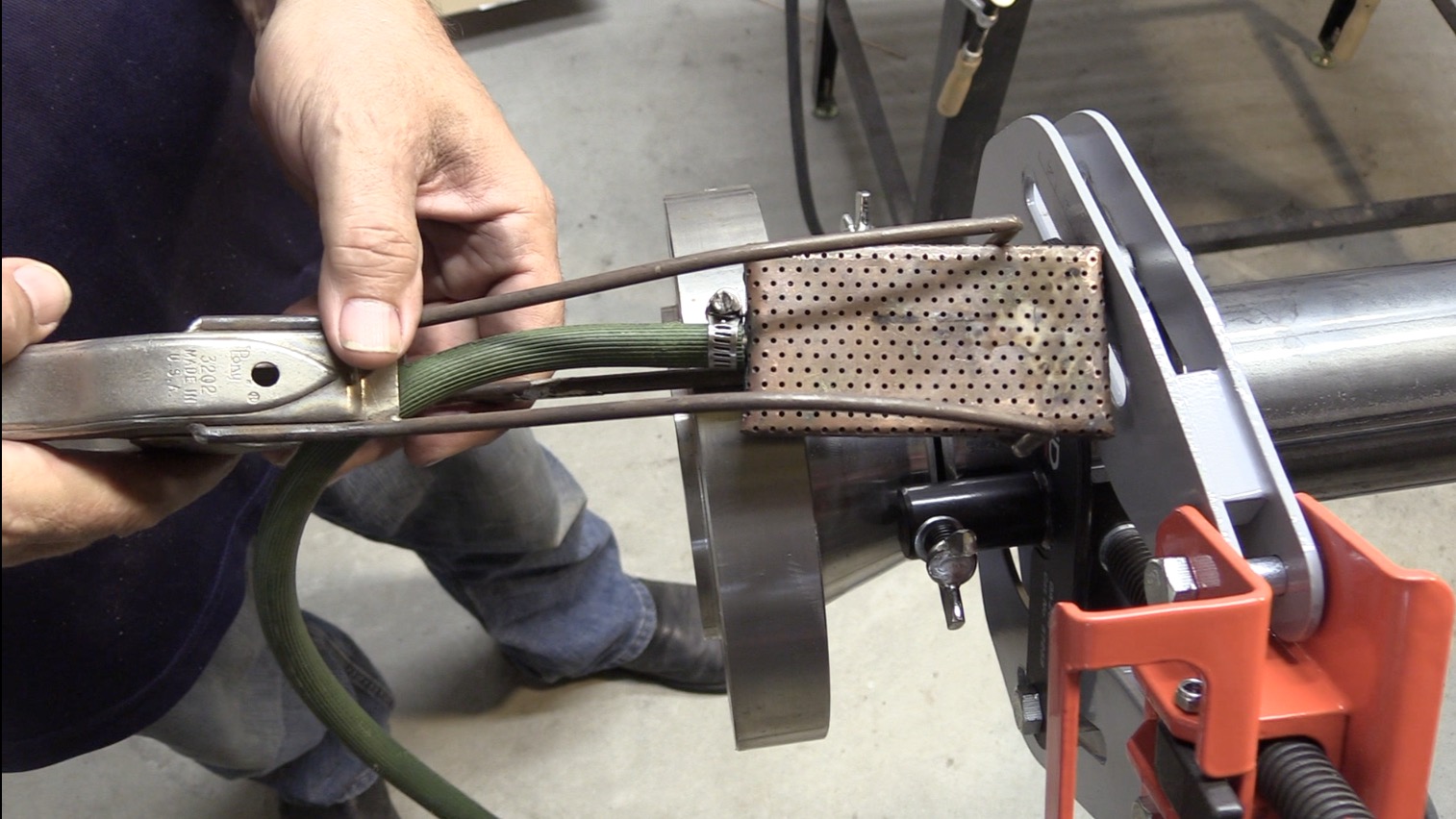

- a diffuser on the end of the purge hose like a sintered bronze air grinder muffler can help greatly

Too much flow can cause turbulence and pull in air. Use just enough to create laminar flow.

Pro Tips

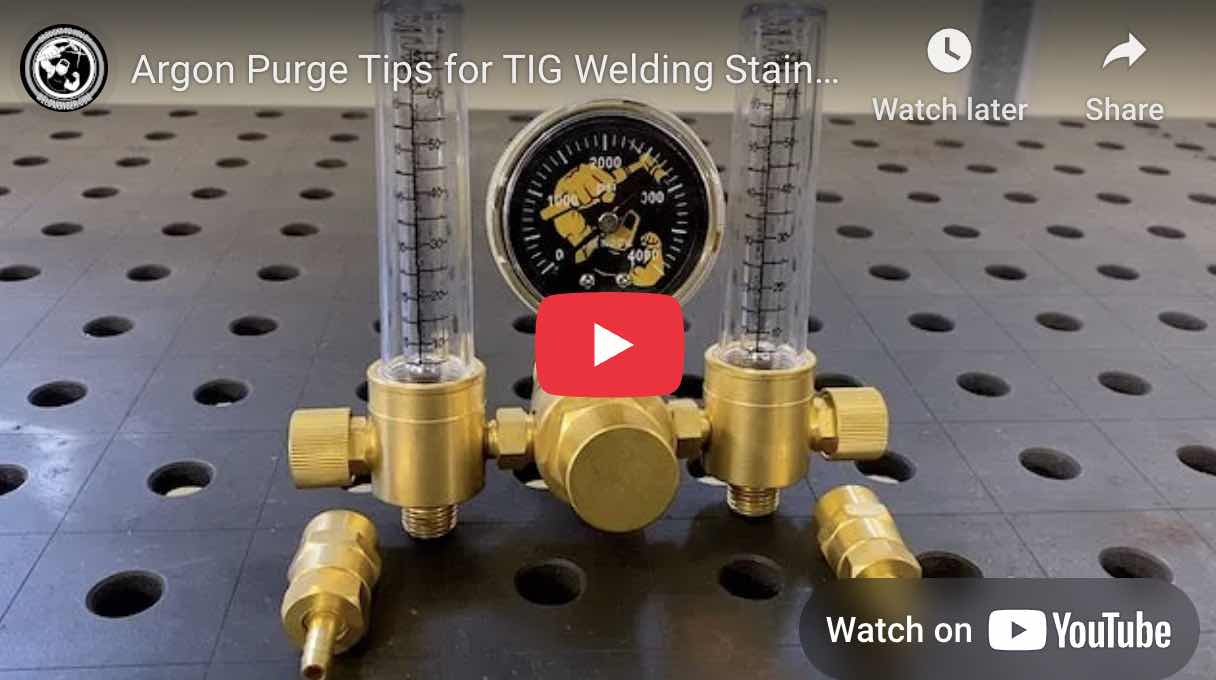

- Use a dual-flow regulator to run torch and purge lines from one tank

- Don’t over-pressurize the pipe—it can cause weld defects

- Use oxygen sensors or purge monitors for critical welds

Weldmonger Dual Flowmeter with lifetime warranty

Alternatives to Full Purging

- fabricate a purge box in the shape needed to apply argon locally

- Copper Chill Blocks or Backing Bars: Provide some shielding and heat control

Backpurging is essential when TIG welding stainless pipe and tube as well as other stainless parts where the penetration side can sugar.

Purging prevents internal oxidation and preserves corrosion resistance and weld quality. With the right tools and techniques, you’ll get clean, code-compliant welds that pass inspection and stand the test of time.

Welding Sanitary Stainless Tubing and Purging

Sanitary Stainless pipe and tube welding requires a high quality argon purge in order to comply with sanitary codes.

Backpurging is not an option with sanitary stainless.

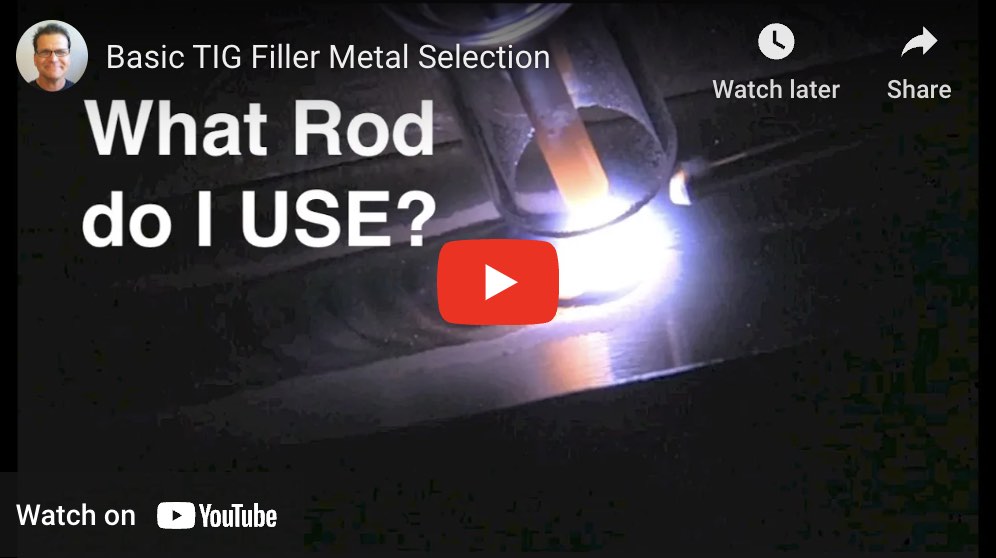

Filler metal for TIG welding 304L stainless

ER308L is the recommended filler rod for TIG welding 304L stainless steel.

Here is a handy stainless filler metal chart for many different grades of stainless steels