DUAL SHIELD FLUX CORE SETTINGS CARBON STEEL 6 INCH PIPE SCHED 80 3/8" WALL THICKNESS

- HOME

- Mig Welder Settings

- Dual Shield

- Dual Shield Flux Core

If you are in business for yourself where time savings adds to your profit, think about dual shield flux core for a great mix of productivity, all position welding, and quality welds.

Another great feature of dual shield flux core, is that a simple mig welder without pulse features can be used.

WELD PROCESS = DUAL SHIELD FLUX CORE, FCAW-G ( GAS SHIELDED)

METAL TYPE = CARBON STEEL PIPE

THICKNESS = 3/8”

WELD TYPE = GROOVE

JOINT TYPE = BUTT

POSITION = ROLLED IN JACK STANDS

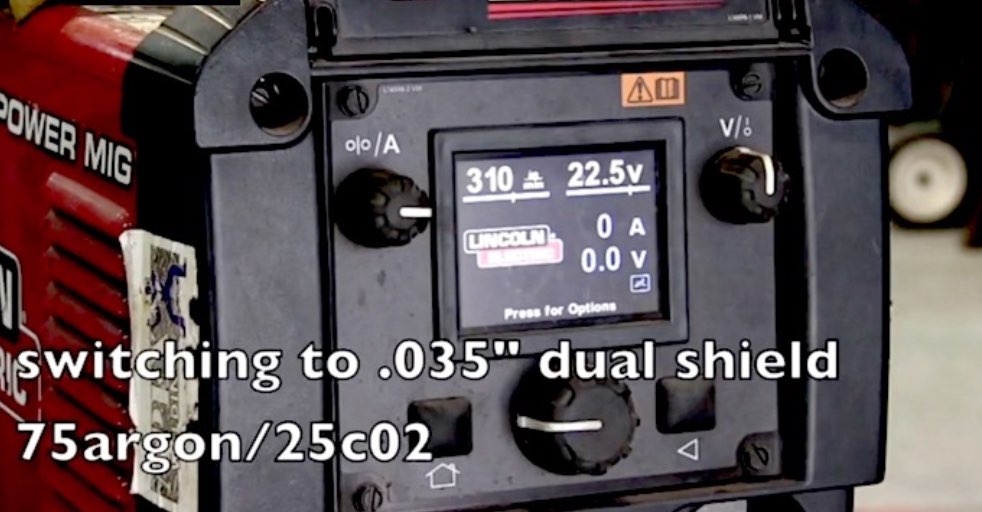

VOLTS = 22.5 volts

WIRE SPEED = 310 IPM

WIRE SIZE = .035” LINCOLN 71M

POLARITY = DCEP

GAS FLOW = 25-30 CFH C25 GAS

CTWD (STICKOUT) = 3/4”-1 “

FILLER METAL = LINCOLN 71M OUTERSHIELD .035"

ADDITIONAL SETTINGS =

TIPS:A longer stickout aka contact to work distance CTWD of 3/4” to 1” provides best results Using too short a stickout can result in worm tracks