Dual Shield flux core Settings FCAW-G Gas shielded flux core

BOOKMARK THIS PAGE FOR DUAL SHIELD FLUX CORE SETTINGS

- HOME

- WELDER SETTINGS

- Dual Shield

2F Horizontal 1/4" thick dual-shield settings

2f position 1/4" plate to box tube with dual shield

3f vertical uphill settings for dual-shield fcaw-g

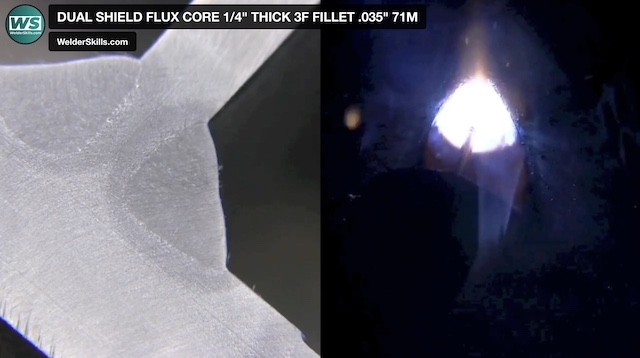

3f position 1/4" thick fillet using .035" lincoln 71m

3f fillet weld tee 3/8" thick using .045" dual-shield

4F Overhead tee dual-shield settings

4f tee joint 1/4" thickness dual-shield flux core

3g Weld Certification test plate vertical uphill 3/8" 10mm thickness with backing plate

3g plate test dual-shield flux core root pass settings

3g fill passes settings for dual-shield fcaw-g

3g cover pass settings dual-shield flux core plate test

4g Weld Certification test plate overhead 3/8" 10mm thickness with backing plate

4g settings for dual-shield flux core test plate root pass

4g plate test settings dualshield fcaw-g fill passes

4g plate test dual-shield cover pass settings fcaw-g

6 inch schedule 80 pipe dual-shield settings

dual shield settings for 6 inch schedule 80 pipe

This page was made to help you find dual shield settings quickly and easily for a few of the most common weld joints.

Dual shield flux core is a trade name and is also called fcaw-g which stands for 'flux cored arc welding gas shielded"

Dual shield flux core excels for out of position welding like vertical uphill and overhead....especially when its not feasible to clean hot rolled mill scale before welding.

One lesser known useful tip for folks who do on site fabrication/installation is that dual shield is available in .035" diameter and can be used very effectively with small machines like the small portable lincoln powermig 210mp and the newer version 211 and 215 multi process machines.

Being able to weld in all positions without cleaning metal perfectly speeds up the work.

And being able to use generator power with a small inexpensive inverter welder opens up a lot of possibilities for small welding businesses.