Picking the Right Filler rod for Stainless TIG welding

- HOME

- Tig Welding Stainless

- Tig Welding Stainless Steel

- Filler Rod for Stainless Tig

Choosing the correct filler rod for TIG welding stainless steel is imortant for achieving strong, corrosion-resistant welds.

With so many different stainless alloys and filler options, it's important to match the right rod to the base material and application.

This guide will help you select the right filler rod for your stainless TIG welding project.

Common Stainless Filler Rod Types

- Use for: 304, 304L stainless steels

- Why: Low carbon content reduces risk of carbide precipitation

- Features: Good corrosion resistance and weldability, readily available

- Use for: Welding dissimilar metals (e.g., mild steel to stainless)

- Why: Higher chromium and nickel content for increased strength and ductility

- Features: Excellent for buffer layers, readily available

- Use for: welding dissimilar metals or when the metal is of unknown composition

- Why: Higher chromium and nickel content for increased strength and ductility and also very crack resistant.. some even use it for tig welding cast iron.

- Features: buttering layers, dissimilar metals, readily available at weldmonger.com if not at local welding supply stores

- Use for: 316, 316L stainless steels

- Why: Molybdenum content improves pitting resistance

- Features: Preferred for marine and chemical environments, readily available

- Use for: High-temp or stabilized stainless steels (like 321)

- Why: Niobium stabilization prevents intergranular corrosion, 321 filler metal which contains a small amount of titanium as a stabilizing agent is an option but 347 filler metal is often recommended due to titanium not transferring as effectively across the arc.

- Features: for applications exposed to heat cycling. Available online at weldmonger.com

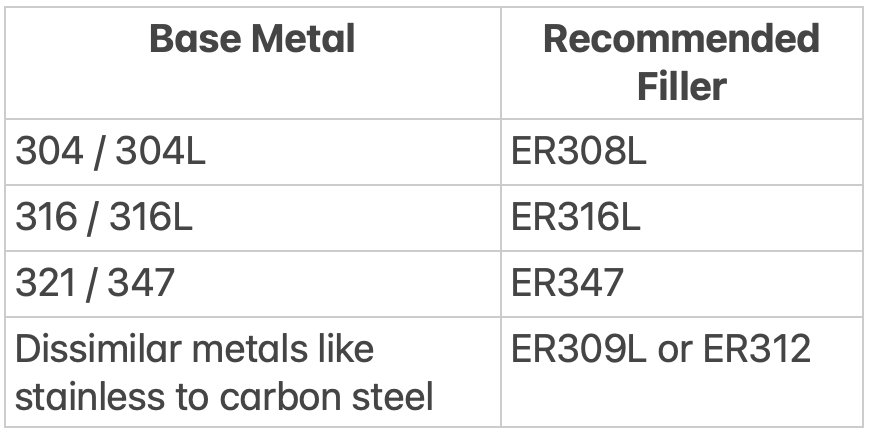

Matching Filler to Base Metal

Always consult a stainless filler metal selection chart from a reliable source (such as Washington Alloys, AWS, or a trusted manufacturer).

Here are a few quick matches:

Considerations Beyond Alloy Match

- Service Environment: Will the weld be exposed to marine, chemical, or high-temp conditions?

- Weld Appearance: Some rods wet out better and make smoother beads

- Availability: Choose rods that are readily available for rework or future repairs

Filler Rod Size and Technique

- Diameter:

- 0.035" to 1/16" for thin material

- 3/32" for 1/8" and thicker

- Technique Tips:

- Dip the filler in at the leading edge of the puddle and keep the hot tip of the filler rod shielded in the argon plume

- Avoid dragging filler out of the argon stream to prevent contamination. Snip tip of filler rod often

Choosing the right filler rod is about more than just matching alloy numbers. It’s about understanding your material, the environment it will be used in, and the expectations of the finished weld. A little research up front can help prevent cracking, rusting, or failure down the road.