GTAW Welding = TIG = Gas Tungsten Arc Welding

GTAW welding TIG welding Carbon Steel, 4130 chromoly, Stainless Steel, Aluminum, and Titanium

- HOME

- TIG WELDING

- Gtaw Welding

You came to the right place for GTAW Welding videos.

There are hundreds of videos here from beginner "how to tig" videos to advanced aerospace welding test videos on titanium.

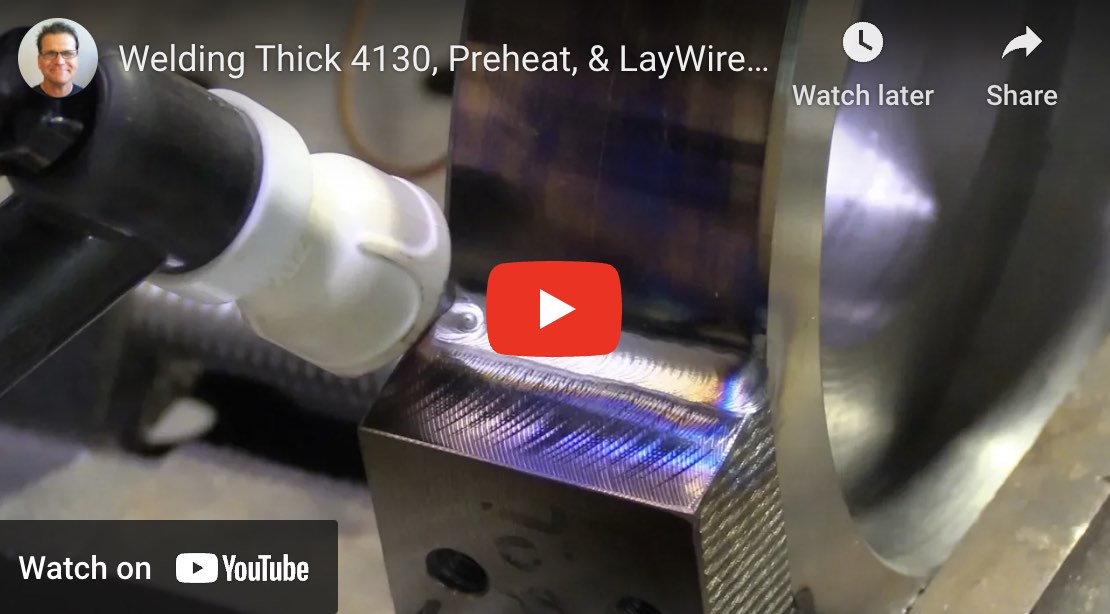

GTAW welding TIG welding 4130

Brad Goodman shows the pulsing with the foot pedal technique on 4130 chromoly

The Video below shows lots of different metals while using several different tig cups

Thick 4130 needs a preheat

GTAW welding TIG welding Stainless and preventing carbide precipitation

GTAW welding TIG welding Aluminum. There are over 100 videos on this site on TIG aluminum.

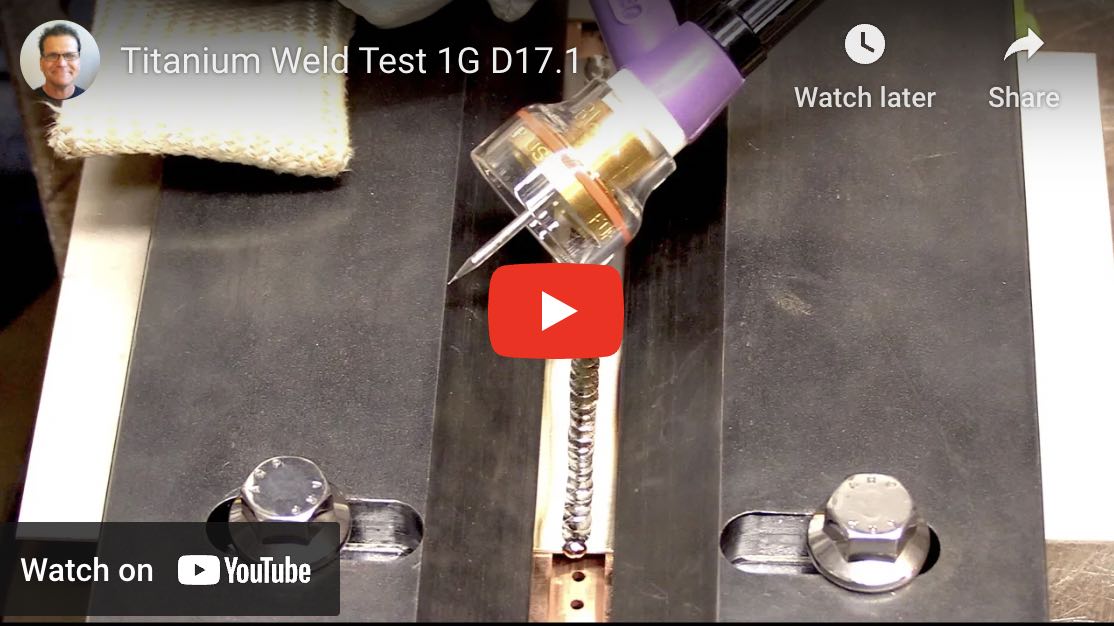

GTAW welding TIG welding Titanium Aerospace Test Tips

GTAW Welding is TIG.

GTAW stands for Gas Tungsten Arc Welding and while this is the correct terminology, its a lot of words so you will hear people say TIG in conversation.

Here are the pros and cons of Gas Tungsten Arc Welding (GTAW), also known as TIG welding:

Pros of GTAW (TIG) Welding

1. High-Quality and precision Welds:

- GTAW produces very clean and precise welds with no spatter or slag. This makes it ideal for welding tasks that require a high level of detail and finish.

The stainless food service, semiconductor, aerospace, and pharmaceutical valve industries all rely on GTAW for clean welds

2. Versatile:

- Can weld a wide variety of metals, including aluminum, stainless steel, magnesium, copper, brass, bronze, and even gold.

- Suitable for both thin and thick materials.

switching from one metal to another is quick and simple and often only requires a different filler metal

3. Control:

- Provides excellent control over the welding arc and heat input, allowing for precise welds. This makes it especially useful for detailed work and delicate materials.

Because an amperage control is often used (either foot pedal or torch mounted amptrol) adjustments can be made while welding intricate parts.

4. Strong, Reliable Welds:

- The welds produced are strong and durable, often used in critical applications such as aerospace, automotive, and piping systems.

GTAW welds are often X ray tested

5. No Filler Metal Required for certain applications:

- Can be done autogenously (without filler metal) which is advantageous for certain types of joints and materials like in some applicaitons like sanitary stainless piping and also kitchen equipment.

6. Cleaner Welding Environment:

- The inert gas shield (typically argon) protects the weld area from contamination, leading to fewer defects and a cleaner work environment.

Cons of GTAW (TIG) Welding

1. Slow Welding Process:

- Compared to other welding methods like MIG or stick welding, GTAW is usually slower, which can increase production time for large projects.

2. Higher Skill Requirement:

- Requires a high level of skill due to both hands as well as a foot sometimes are used. Beginners may find it challenging to produce high-quality welds consistently.

3. More Expensive:

- The equipment for GTAW (including the welding machine, tungsten electrodes, and shielding gas) can be more expensive than other welding methods.

Metal often require more cleaning and prep than other welding processes like mig, flux core, or stick welding.

4. Not Ideal for Outdoor Use:

- The shielding gas can be blown away by wind, making it less effective in outdoor or drafty environments.

5. Limited Portability:

- GTAW welding setups are often less portable compared to other methods like stick welding, due to the need for shielding gas.

GTAW (TIG) welding offers high precision, control, and the ability to weld a wide range of metals, but it requires significant skill, can be slower, and may incur higher costs. It's best suited for applications where the quality and precision of the weld are paramount.