How do YOU MIG Weld?

Start Here

Setting up a MIG welder (PrimeWeld MIG180)

Check out our MIG Welding Basics Series

learn more about the MIG 180 at weldmonger.com

- HOME

- MIG WELDING

- How Do You Mig Weld

Setting up a MIG welder (Hobart 210)

If you are looking for the answer to "how do you mig weld?" this page will give you a jump start.

Some key points to get started on the right foot:

- Make sure the contact tip and drive rollers are matched to the wire size

- Make sure the contact tip is flush or slightly protruding past the nozzle

- Make sure the tension on the wire spool is just enough to stop the spool from spinning when the mig gun trigger is released

- Make sure the tension on the drive rolls is just tight enough to not slip as shown in videos

MIG wire speed Settings

learn more about the MIG 180 at weldmonger.com

Wire speed controls amperage but you also need to have enough voltage for a smooth arc.

There is quite a bit of leeway when it comes to wire speed settings but the one thing you want to avoid is setting the wire speed extremely low just for the sake of a pretty bead. That sacrifices penetration.

In the video above on wire feed speeds, you will see that the beads welded with 236 inches per minute of WFS does not look much different than the bead welded at 173 ipm. That just goes to show that there is a fairly wide range that can work for a given situation.

Just think if you are welding a project like a welding cart...

You dont need to change wire speed for every different weld. Overhead, Vertical, tee joints, butt joints, all can be welded with the same wire speed once you get it dialed in,

The best bang for the buck MIG welding practice

The best way to improve your mig welding as a beginner is to practice stacking beads on a piece of scrap metal.

This can be done on 11ga steel , 3/16", or even thicker but since 11ga is cheapest, that is a good choice.

Practice padding beads halfway over the previous bead.

Practice welding right to left, left to right, pushing and pulling.

practice keeping your gun angle and stickout consistent.

Make sure to watch the video periodically to stay on the right track.

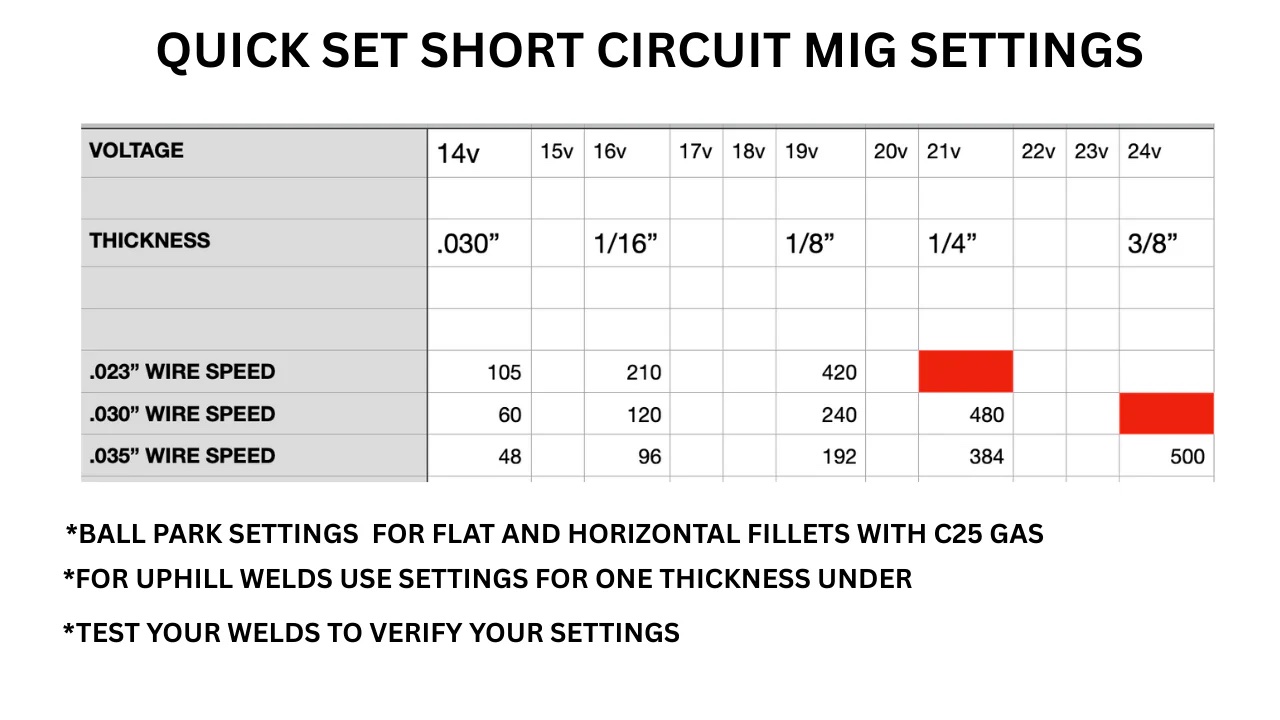

MIG Charts and Settings

You can usually use the settings that are listed on most mig welding machines as a starting point but just remember that those settings are intended for flat and horizontal fillet welds and tend to be a bit high.

For vertical uphill, use lower settings.

Here is a much simpler chart if you are using C25 gas