How does mig welding work?

MIG welding, also known as Metal Inert Gas welding or Gas Metal Arc Welding (GMAW), is a popular welding process that uses a continuous consumable bare wire electrode and shielding gas to join metals together.

- HOME

- How to Mig Weld

- How Does Mig Welding Work

learn more about the MIG 180 at weldmonger.com

Here's a beginner-friendly explanation of how MIG welding works:

- Welding Setup: To begin MIG welding, you'll need a mig welding machine, a spool of mig welding wire, and a cylinder of shielding gas. The shielding gas, typically a mixture of argon and carbon dioxide, is used to protect the welding area from atmospheric contamination. This is how mig welding differs from self shielded flux core welding where no gas is needed. MIG welding requires shielding gas and the most common gases are C25 (75/25 argon/co2) and pure CO2.

- MIG gun: when you press the trigger on the mig gun, 3 things happen... wire feeds thru the end of the nozzle, shielding gas starts flowing thru the nozzle to protect the weld, and welding current turns on. The current flows through the welding gun and the wire electrode, creating an arc between the electrode and the workpiece.

- Wire Electrode: The wire electrode, which is fed continuously from a spool, acts as both the filler metal and the electrode. It is made of a specific type of metal alloy that matches the material being welded. For carbon steels, the most common mig wire is ER70s-6. As the wire electrode is fed through the welding gun, it creates an arc that melts and fuses with the base metal.

- Arc Formation: When the electrode wire and the workpiece make contact, an electric arc is formed. The arc produces intense heat, reaching temperatures high enough to melt the metal. The heat from the arc causes the electrode wire to melt, creating a small pool of molten metal on the workpiece.

- Shielding Gas: The shielding gas is released through the welding gun, surrounding the arc and the molten metal pool. This gas forms a protective shield, preventing the molten metal from reacting with oxygen and nitrogen in the air, which could lead to defects in the weld. The gas also helps to cool the welding area.

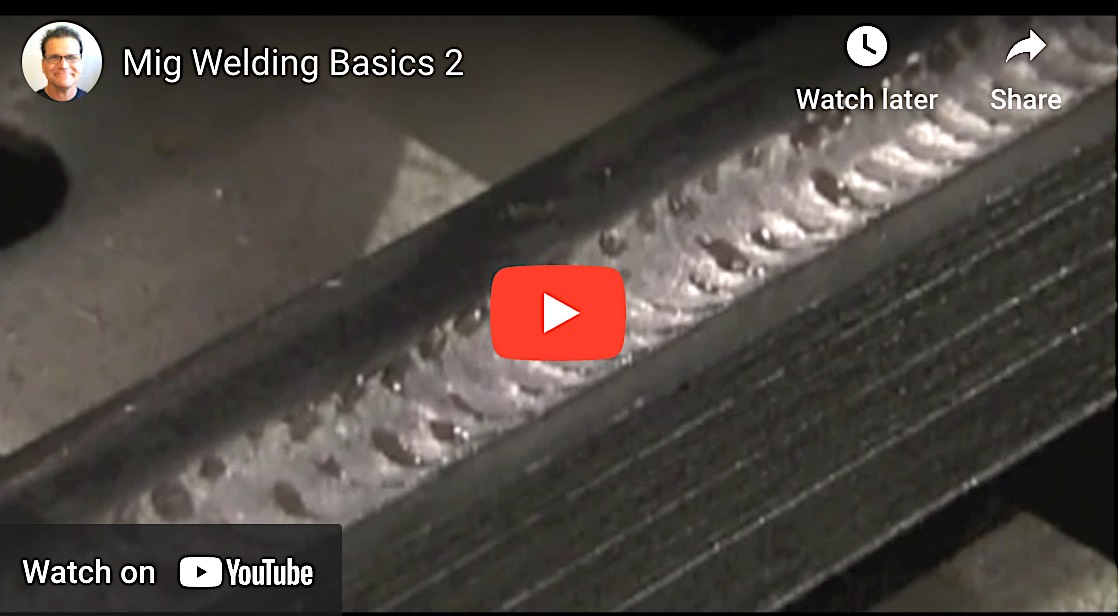

- Welding Process: To start a weld, the welder points the mig gun where he wants to start with the nozzle within about 1/2" from the starting point and then moves the welding gun gradually along the joint where the metals need to be joined. As the welder moves the gun, the molten metal from the electrode wire is transferred into the weld pool. The weld pool solidifies, creating a strong bond between the base metals.

- Filler Metal: In MIG welding, the filler metal is automatically fed into the weld pool from the welding wire. The filler metal helps to reinforce the joint and create a stronger weld. The wire is fed at a controlled rate, determined by the welding machine settings and the welder's manipulation.

Overall, MIG welding is a versatile and relatively easy welding process to learn. It is commonly used in various industries and applications, including automotive, fabrication, and construction, due to its speed, efficiency, and ability to weld a wide range of metals.

Practice, proper safety precautions, and understanding the equipment are essential for successful MIG welding.