TIG Weld Tungsten Guide – Complete Guide to Choosing the right Tungsten for your job

- HOME

- TIG WELDING

- Tig Weld Tungsten

See most recent videos here

Introduction to TIG Welding and Tungsten Electrodes

What is TIG Welding?

TIG welding, short for Tungsten Inert Gas welding, is one of the most precise and cleanest welding processes available today.

The more proper term for TIG welding is Gas Tungsten Arc welding.(GTAW).

It uses a non-consumable tungsten electrode to produce the arc and heat, accompanied by an inert gas, typically argon, to shield the weld area from contamination.

This method allows for superior control over the weld bead and heat input, making it ideal for welding thin materials or creating intricate welds. Unlike MIG welding, TIG doesn’t automatically feed a filler wire—you add it manually, giving you the ability to make pinpoint adjustments during welding.

TIG is used extensively in industries that require clean, high-quality welds, such as aerospace, automotive, and fabrication. One of the biggest advantages of TIG welding is its versatility—you can use it on a variety of metals, including stainless steel, aluminum, copper, magnesium, and more.

However, it also requires more skill and practice compared to other methods. The core of TIG welding lies in the tungsten electrode, which doesn’t melt but conducts the heat necessary to melt the base metal and filler rod.

Without tungsten, TIG welding simply wouldn’t exist.

The Role of Tungsten in TIG Welding

Tungsten plays a key role in TIG welding because of its unique properties. It has the highest melting point of any metal—over 6,000°F (3,400°C)—which allows it to maintain a stable arc without degrading quickly.

During the welding process, tungsten carries the electric current needed to generate the arc and melt the metal, but it doesn’t itself melt or get consumed like a filler rod.

For this reason, text books state that TIG welding uses a "non consumable" electrode. This can be confusing because Tungsten is definitely a consumable in TIG welding due to constant resharpening.

This stability makes tungsten ideal for producing precise, controlled welds. Different types of tungsten electrodes have different characteristics, such as arc stability, longevity, and ease of starting the arc, which is why selecting the right one can make or break a weld. For example, some types are better suited for alternating current (AC), such as when welding aluminum, while others work better with direct current (DC) for steel or stainless steel. Moreover, the tip geometry—whether it’s pointed, balled, or truncated—also affects the arc shape and penetration. Simply put, without the right tungsten setup, even the most experienced welder will struggle to achieve consistent, clean results.

We have tungsten Holders with Color coded bands

at weldmonger.com

We put together this tungsten bundle because 3/32" is the most versatile and most commonly used tungsten but you still need a few 1/16" and 1/8"..

you know what I mean???

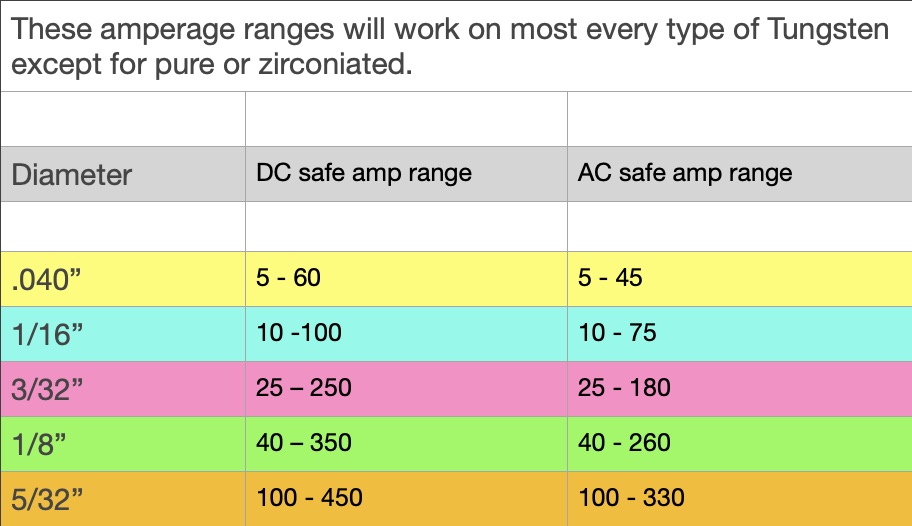

If you have every looked for a chart on the amperage ranges for different diameter tungsten electrodes, you might be as shocked as I was to see the maximum amperage for 1/16" tungsten at 150 amps.

The chart below lists a much more reasonable amperage range.

Selecting the right diameter of tungsten electrode can be just as important as choosing the right type.

Too small, and it’ll overheat and deteriorate quickly. Too large, and it might be hard to get a stable arc, especially at lower amps.

As a general rule, smaller diameter electrodes (like 1/16” or 1.6mm) are used for low-amperage applications such as sheet metal or precision welding. Larger diameters (3/32” or 2.4mm, even up to 1/8” or 3.2mm) are suited for high-amperage, heavy-duty welds but can also be used at fairly low amperage depending on how you prepare the point.

The tip geometry plays a role in how the tungsten reacts to the amperage. Pointed tips make for better arc starts, while balled tips distribute the arc cone more broadly. Make sure your tungsten type is compatible with the amps you plan to run—thoriated and lanthanated types handle higher amps better, while pure tungsten should be kept on the lower end.

If your electrode tip begins to quiver or deform during welding, that’s a sign you’re exceeding its optimal amperage range.

Types of Tungsten Electrodes

Pure Tungsten (Green)

Pure tungsten electrodes, marked with a green color, are the most basic type and are composed of 99.5% tungsten. They’re typically used with AC welding, especially for aluminum and magnesium. These electrodes form a clean, balled tip when heated, which provides a stable arc with good cleaning action on oxidized surfaces. However, pure tungsten doesn't hold up as well under high amperage and can degrade faster than other types. This means they’re not ideal for all situations in AC welding. They are best suited for beginner welders who are learning TIG on softer metals with lower amperage settings. Despite being the least expensive, their performance limitations have led many professionals to move towards doped tungsten variants like lanthanated electrodes for improved efficiency, longevity, and arc control.

Still, green tungsten remains a popular choice when working with AC on aluminum with older transformer design TIG welders.

Thoriated Tungsten (Red)

Thoriated tungsten electrodes are widely regarded as one of the best options for DC TIG welding. Identified by a red stripe, these electrodes typically contain 2% thorium, a radioactive additive that enhances arc stability, makes it easier to start the arc, and increases the electrode’s durability under higher amperage. They are commonly used for welding carbon steel, stainless steel, nickel alloys, and titanium. Because of their excellent electron emission capabilities, they maintain a sharp point longer, which leads to better arc precision and penetration.

However, the radioactive nature of thorium does come with safety concerns—grinding the electrode can release harmful dust particles. Proper safety equipment and ventilation are a must when working with thoriated tungsten.

Despite the reported safety issues, many experienced welders prefer them for their reliability and consistent arc quality, especially in critical applications where weld quality is non-negotiable. If you're doing mostly DC welding on steel, low alloy steels, stainless, nickel, titanium, copper, or other alloys where DC welding is required, thoriated tungsten is a solid, time-tested choice.

Ceriated Tungsten (Orange or Gray)

Ceriated tungsten electrodes, often marked with orange or gray color codes, contain around 2% cerium oxide. They are excellent for both DC and low-amperage AC welding and are especially useful in applications requiring a smooth, stable arc at low settings. This makes them a go-to choice for welding thin sheet metals, such as those found in HVAC systems or small-scale aluminum projects.

The added cerium enhances arc starts, reduces electrode erosion, and helps maintain a pointed tip longer. This precision is highly valued in industries like aerospace and electronics. While ceriated tungsten doesn’t have the same high amperage durability as thoriated or lanthanated variants, it offers superb performance at lower amps. This is especially important when welding delicate metals where too much heat can cause warping or burn-through. Thanks to their ease of use and low risk compared to radioactive thoriated tungsten, ceriated rods are becoming increasingly popular among professionals who require clean starts and smooth arcs on thinner metals.

2% Lanthanated Tungsten (Blue)

2% Lanthanated tungsten is one of the most versatile and popular choices for both AC and DC TIG welding.

2% Lanthanated tungsten combines many of the advantages of both thoriated and ceriated electrodes, such as excellent arc starting, long electrode life, and good arc stability, without the radioactive risks. They work well on a wide range of materials—from aluminum and magnesium to steel and stainless steel—and they’re suitable for both high and low amperage settings.

What really sets 2% lanthanated tungsten apart is its ability to retain a pointed tip, even under higher loads. This results in better directional control of the arc and improved weld quality. Because of its performance, durability, and safety profile, lanthanated tungsten is quickly becoming the standard in many professional shops. If you're looking for a dependable all-purpose electrode, this one is hard to beat.

E3, CK LaYZr, and rare earth blends

E3, LaYZr, and rare earth blends electrodes represent the cutting edge of TIG welding technology. Rare earth types are alloyed with a mix of oxides, providing benefits like improved arc stability, longer life, and better performance across a broad range of metals. They're often seen as "universal" electrodes that can replace multiple other types with one solution.

E3 and LaYZr from CK Worldwide are very similar and perform well at mid range amperage on AC and also have excellent arc starts on DC.

Zirconiated tungsten, marked with a white band, contains zirconium oxide and is best used for AC welding, particularly aluminum. It balls like pure tungsten, but carries more amperage than pure tungsten.

How to Choose the Right Tungsten for Your Project

AC vs DC Welding Considerations

Choosing between AC and DC welding plays a big role in which type of tungsten you should use.

Each current type interacts with tungsten differently, affecting arc performance, tip shape, and electrode longevity.

When welding with AC (alternating current), which is commonly used for non-ferrous metals like aluminum and magnesium, the current alternates between positive and negative. This helps clean the oxidation off the metal surface but also puts more heat on the tungsten electrode.

In this case, using a tungsten type that can maintain tip shape, like 2% lanthanated, E3, or CK LayZr, is ideal.

On the other hand, DC (direct current) welding—particularly DCEN (Direct Current Electrode Negative)—is mostly used for ferrous metals like carbon steel and stainless steel. DCEN provides a stable arc, deeper penetration, and a focused heat zone. For DC welding, thoriated, ceriated, or lanthanated tungsten is preferred because they maintain a sharp point, offer excellent arc stability, and have better heat resistance.

The good news is you don't need a different tungsten for each different application.

Either 2% lanthanated or CK LaYzr tungsten are great choices for all purpose tungsten electrodes that perform well on everything.

Proper Preparation and Sharpening of Tungsten Electrodes

In my opinion, the primeweld 225 is one of the best choices in affordable tig welders.

The problem with most other really affordable tig welders is usually the foot pedal and the torch are just bad and clunky.

Primeweld went to extra expense to include genuine ck torches with superflex hoses along with a smooth SSC style foot pedal.

They also have a responsive primeweld equipment users group on facebook and also have demonstrated great customer support

Watch some primeweld videos and you will see what I mean.