Simple Welding Metallurgy for Aluminum

...Boiled Down for Welders

Watch the latest welding videos at Weldmonger.com

- HOME

- TIG WELDING ALUMINUM

- How to Tig Aluminum

- Simple Welding Metallurgy

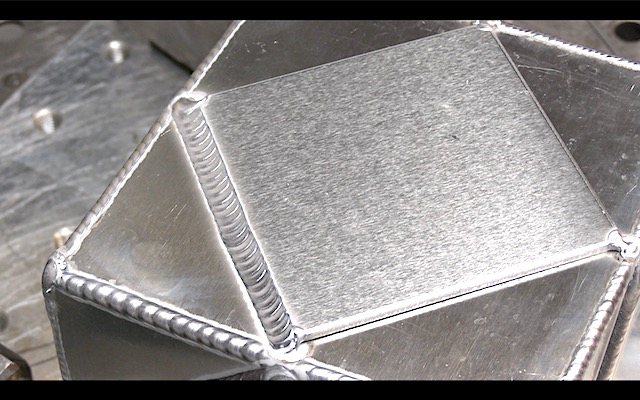

Video Shows 7 Tips for TIG Welding Aluminum

Simple Welding Metallurgy as It Applies to Welding Aluminum, written in clear, practical language for welders, fabricators, and students:

Aluminum is a lightweight, corrosion-resistant alloy that is widely used in everything from aircraft parts, to ladders to automotive parts.

But aluminum doesn’t exactly behave like steel when you weld it—

for example, while carbon steel can harden if you heat it and quench it rapidly, aluminum gets softer from heating and quick cooling....and if you don’t understand a few basic metallurgy principles like this, you can end up with cracks, porosity, or soft/weak zones that ruin the properties.

This article covers the key points of aluminum metallurgy that every TIG or MIG welder should know: from surface prep and filler selection to how welding affects the metal’s properties.

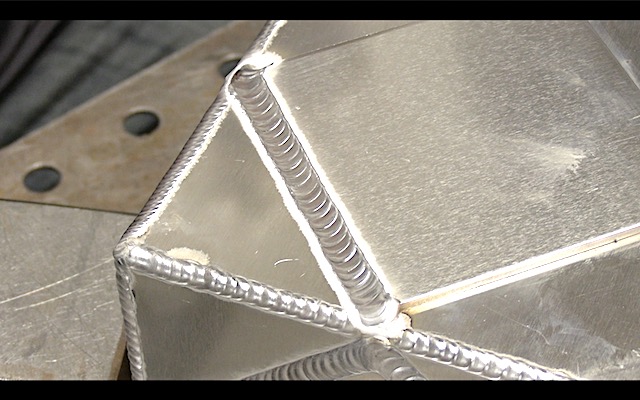

Surface Prep Tips for TIG Welding Aluminum

They say the 3 C’s of Tig welding aluminum are:

- CLEAN

- CLEAN

- CLEAN

but are there exceptions to this? keep reading

ALL ALUMINUM naturally forms an oxide layer (aluminum oxide) that melts at over 3,700°F—while the base metal melts around 1,200°F.

That is why aluminum is typically welded using Alternating current (AC).

The reverse (electrode positive) portion of the AC cycle provides a cleaning action that is beneficial in breaking up the aluminum oxide layer that is on the surface all aluminum:

But that doesn’t mean that all aluminum needs stringent cleaning before TIG welding.

What?

That probably goes against what all text books recommend but it is just reality.

I am NOT saying that ALL aluminum can be welded with ZERO cleaning.

But Not all aluminum requires wire brushing or abrasive cleaning before welding.

In fact, you would most likely get fired at a lot of manufacturing facilities if you put wire brush marks on aluminum parts.

There is a big difference between brand new aluminum tubing, and an aluminum handrail near the ocean.

Brand new aluminum can usually be tig welded with only a simple wipe down to remove shop dust.

That heavily oxidized aluminum handrail that has been exposed to salt air, will almost always need cleaning using wire brushes, wire wheels, or abrasives to remove the heavy layer of oxide.

- If a heavy oxide layer isn’t removed, you’ll get a dirty weld, along with poor fusion.

Surface prep checklist:

- Degrease with acetone or a dedicated aluminum cleaner (no oil-based solvents).

- Wire brush with a dedicated stainless steel brush (never use one that’s touched steel).

- Don’t overbrush with high RPM wire wheel—you can smear oxide into the surface.

- If needed, use debur tool to scrape or use file on edges to expose clean metal right before welding…especially on plasma cut edges.

Also, weld as soon as possible after cleaning to prevent fresh oxide or moisture from forming.

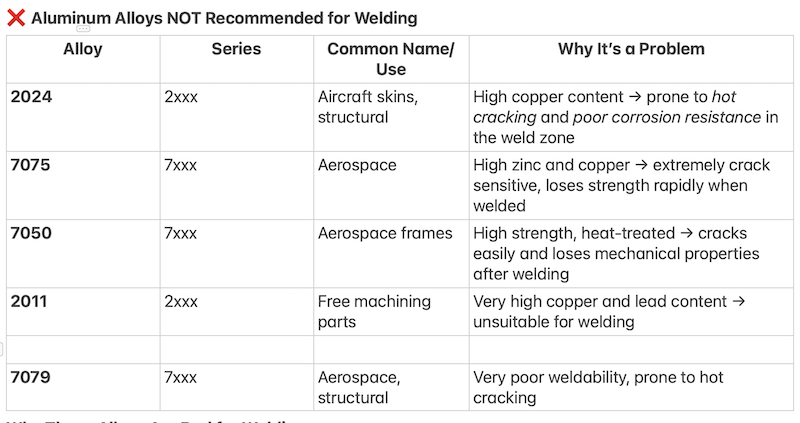

🚫 Which Aluminum Alloys Should NOT Be Welded?

Not all aluminums are weldable—even if they look the same. Some crack very easily when tig or mig welded, especially certain high-strength grades.

2024 and 7075 are the 2 main aluminum alloys not recommended for welding.

Both are heat treated for high strength and lose much of that strength if welded using arc welding processes like tig or mig.

But how do you tell if a part is made from 2024 or 7075?

The first clue is to look for prior welds on the part.

If there are mechanical fasteners like rivets or screws in areas where it would have been easier to weld it, then it is likely the part is made from either 2024 or 7075.

There are also chemical tests to determine aluminum alloy types but they not readily available and require some training and experience to use effectively.

🔧 Filler Metal Selection – Get It Right the First Time

Using the wrong filler can lead to:

- Cracking

- Loss of strength

- Corrosion

- color mismatch

This chart for filler metal selection is a great resource

...pro tip: make sure to read footnotes

https://www.hobartbrothers.com/downloads/aluminum_selecti_1lOo.pdf

🔥 What is Hot Shortness?

Hot shortness is when aluminum cracks while it's still partially liquid during cooling. It happens because:

- Some alloys form low-melting eutectic phases at grain boundaries.

- These melt too early or too late in the weld cycle and lead to liquation cracking.

This is why certain alloys (like 2024 or 7075) are not recommend for welding—they’re full of elements like copper or zinc that create low melting eutectics.

🛡️ Why Are Some Aluminum Parts Anodized After Welding?

Anodizing is an electrochemical process that:

- Builds up the oxide layer

- Improves corrosion resistance

- Enhances appearance (especially in architectural parts)

But welding destroys the anodized layer in the weld zone. That’s why:

- Anodizing is done after welding if possible

- Color mismatches can happen if welds aren’t properly cleaned or blended consult this filler metal selection part to make sure to choose a filler metal that will respond favorably to anodizing after welding https://www.hobartbrothers.com/downloads/aluminum_selecti_1lOo.pdf

Some parts are chemically brightened or clear anodized after welding to restore a uniform finish and corrosion protection.

🧊 What about Loss of Temper in the HAZ (Heat-Affected Zone)?

Many aluminum alloys are heat-treatable (like 6061-T6). Welding softens the area around the weld, known as the HAZ. This happens because:

- The precipitates that give the alloy its strength dissolve into the alloy matrix.

- The weld is often stronger than the surrounding softened area, causing failure in the HAZ.

How to manage temper loss:

- Design around it: don’t expect full T6 strength after welding.

- Use a proven procedure produces adequate strength in the haz.

- Post-weld aging or re-heat treating may be required (but not always practical).

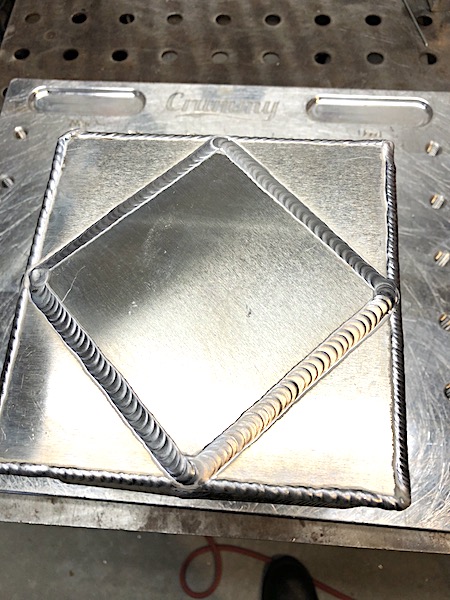

Welding aluminum isn’t just about melting metal—it’s about understanding the material. Here's what matters most:

- Prep like a pro—oxides and grease will ruin the weld.

- Know your alloy—some aluminums are best left unwelded.

- Choose filler wisely—and use charts when in doubt.

- Watch out for hot shortness - inspect welds for cracking especially on starts of fillet welds and craters where the weld is terminated

- Expect some temper loss—and plan your design around it.

- Post-weld anodizing helps restore function and finish.

...Introducing the New WeldMonger Challenger TIG kit that includes the most frequently used Cups.

Furick Ally #5 clear cup

Furick 8 pro Etch zone

Ally #5 etch zone

There is a great thread about tig cups for aluminum on my forum