Stainless TIG Welding Rods along with Videos on How to TIG weld stainless steel

- HOME

- Tig Welding Stainless

- Tig Welding Stainless Steel

- Stainless Tig Welding Rods

TIG welding filler metal is in stock at Weldmonger.com

Stainless TIG Welding Rods: Choosing Between ER308L, ER316L, ER347, and ER312

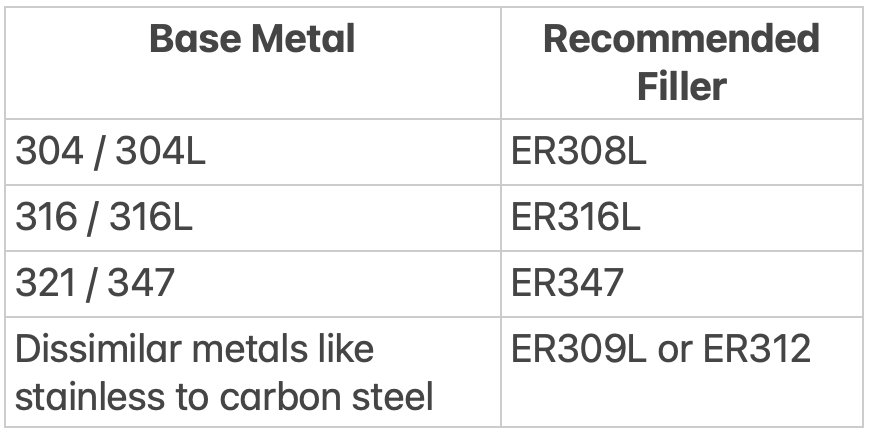

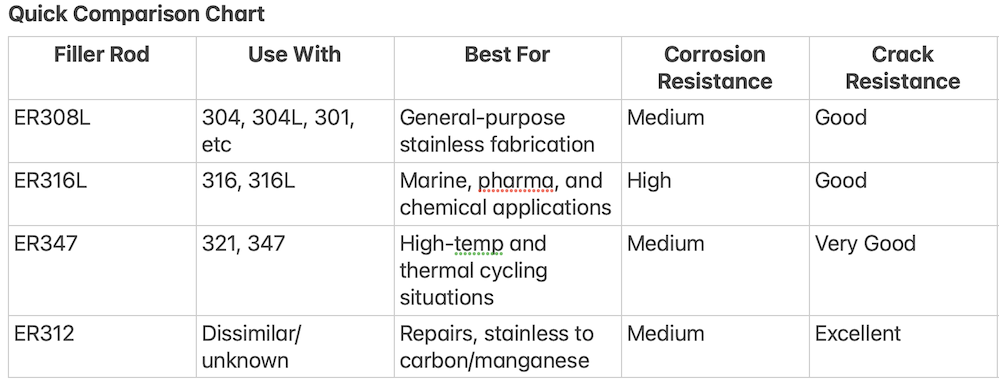

Selecting the right filler metal is one of the most important decisions in TIG welding stainless steel.

The rod you choose affects everything from corrosion resistance to weld strength and crack resistance. In this article, we’ll look at four of the most commonly used stainless TIG filler rods:

ER308L, ER316L, ER347, and ER312—including what they’re for, when to use them, and what makes each unique.

Common Stainless Filler Rod Types

1. ER308L – The Go-To Rod for 304 Stainless

What it’s for:

ER308L is the most commonly used filler metal for welding 304 and 304L stainless steel. It’s ideal for general-purpose stainless fabrication and offers a good balance of weldability, corrosion resistance, and affordability.

Key Characteristics:

- “L” stands for low carbon, which helps prevent carbide precipitation and cracking.

- Excellent for structural work, kitchen equipment, railings, and automotive parts.

- Good toughness

Use When:

- Welding 304, 304L, 301, 302, 303 free machining or similar stainless types.

- Working on food-grade or cosmetic-quality stainless where weld color matters.

2. ER316L – Better for Corrosive Environments

What it’s for:

ER316L contains molybdenum, which improves resistance to pitting and corrosion—especially in chloride environments (like saltwater, chemicals, or industrial atmospheres).

Key Characteristics:

- Higher corrosion resistance than 308L.

- Still low in carbon for improved resistance to intergranular corrosion.

- Common in marine, chemical processing, and pharmaceutical applications.

Use When:

- Welding 316, 316L, or 316Ti stainless steel.

- Corrosion resistance is a top priority (e.g., saltwater exposure).

- Welds will be exposed to acids or chlorides.

3. ER347 – For Heat-Cycled or High-Temp Stainless

What it’s for:

ER347 is stabilized with niobium (columbium) to prevent carbide precipitation during high-temperature service. It’s a great choice for stainless that will go through thermal cycling or high-temperature operation.

Key Characteristics:

- Offers excellent creep strength at elevated temperatures.

- Resists intergranular corrosion even after prolonged heat exposure.

- Ideal for exhaust systems, furnace components, and power generation equipment.

Use When:

- Welding 321, 347, or other stabilized grades of stainless.

4. ER312 – For Dissimilar metals or Crack sensitive Stainless

What it’s for:

ER312 is a high-strength, high-ferrite rod that’s designed to weld dissimilar metals and resist cracking in difficult-to-weld stainless alloys. It's often used for maintenance and repair.

Key Characteristics:

- High tensile strength (over 125,000 psi).

- Not alloy-specific—works across many stainless and carbon grades.

- High ferrite content improves crack resistance under stress or mismatched expansion rates.

Use When:

- Welding stainless to carbon steel, manganese steel to stainless, and pretty much any steel to any other steel.

- The base metal is unknown, or difficult to match.

- Repairing cracked stainless parts or castings.

Final Tips for Filler Rod Selection

- Always match the filler to the base material whenever possible.

- For food-grade or high-corrosion environments, go with ER316L or ER347.

- For repairs, unknown metals, or difficult welds, ER312 can be a lifesaver.

- Keep rods clean and dry—stainless filler rods are prone to contamination.