Steel Tig welding Settings

- HOME

- TIG WELDING

- Steel Tig Welding Settings

TIG Welder Settings for Carbon Steel...From Thin to Thick

Tig welding carbon steel from .063" - 1.00"

(1.6mm- 25mm) settings

Tig Welder Settings for Carbon Steel Fillet Welds

Steel TIG welding settings made easy

All TIG machines are somewhat different but here are some basic principles to help you with your steel tig welding settings...

Polarity should be on DCEN

On older transformer style machines set high frequency to start.

On newer inverter tig welders set process to TIG and DC.

if pre flow setting is available set to around half a second.

post flow set from 7-10 seconds

if 2t 4t setting is available set to 2t when using a foot pedal

set upslope and downslope to zero

set pulser to off

Amperage should be set to around one amp per one thousandths of thickness plus around 10% extra if using a foot pedal. ( this one amp per one thou rule only holds true up to around .125" thickness)

a #7 tig cup is a good all around cup for steel and needs 14-21 CFH argon flow rate.

a 3/32" 2% lanthanated tungsten will take care of anything a 200 amp tig welder can do. I like to sharpen mine to a 30 degree taper for tig welding steel.

ER70S-6 is a great choice for filler rod for tig welding steel

ER70S-2 is more readily available in welding supply stores and for the most part will work just fine for tig welding steel.

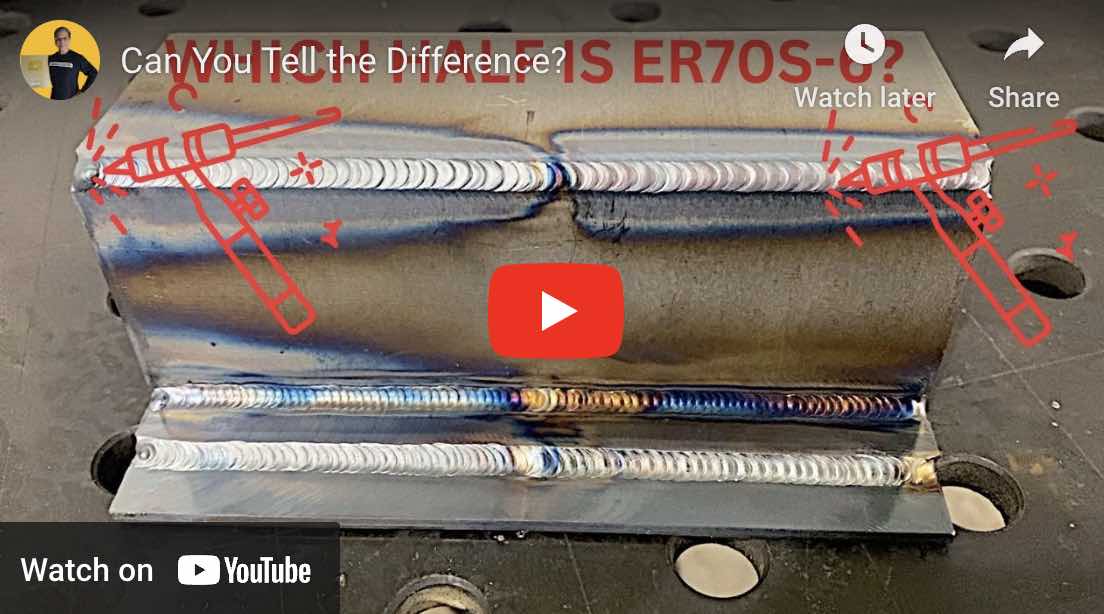

Here is a video tig welding steel with both ER70S-2 AND ER70S-6.