Structural Welding Test 2g, 3g, 4g, with 7018...Lets Go!

first...the 3G structural welding test

For premium videos on passing welding tests...

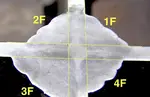

When you hear someone talk about a structural welding test, a very common weld test is actually Two welds...a 3g as well as a 4g plate test with 7018.

3g is vertical uphill and 4g is overhead.

4G overhead structural welding test

an old timer once told me "overhead is just flat..but upside down"

The amperage needed for a 4G overhead plate test is pretty close to what you might use for a 2g.

A mistake some new welders make is turning the amperage down for fear of the weld sagging.

Some codes might require a 2G plate too

AWS D1.1 is the main structural welding code and has provisions for doing this test with several welding processes including Shielded metal arc welding with 7018 stick electrodes, Dual Shield Flux core, and Self Shielded flux core.

The reason a lot of companies give both 3G and 4G plate tests is that when you pass both of these plates, you are qualified to weld all positions.

Some other codes might also require a 2G plate.

Construction companies often require both a 3G and 4G welding test for structural welding certification for several reasons:

- Skill assessment: The 3G and 4G welding positions represent different types of welding joints. The "G" refers to the type of weld ...groove, with "3G" being a vertical groove weld and "4G" being an overhead groove weld. By testing candidates in both positions, construction companies can assess their ability to weld in various orientations, demonstrating a broader skill set.

- Job requirements: Structural welding in construction often involves welding in all different positions, including vertical and overhead positions, but also with other constraints and limited access to weld joints. Construction companies need to ensure that certified welders can perform effectively in all situations to meet the specific demands of structural projects.

- Code compliance: Welding standards and codes, such as those established by the American Welding Society (AWS), often require specific certifications for different welding positions as well as thickness and material type. By testing welders in both 3G and 4G positions, construction companies ensure compliance with industry standards and codes.

- Versatility: Welders who can successfully pass both 3G and 4G welding tests demonstrate versatility and adaptability. They can handle a wider range of welding tasks and are more likely to be qualified for various construction projects that may involve different welding positions.

Requiring both 3G and 4G welding tests for structural welding certification allows construction companies to assess a welder's skills in different positions, and get more bang for the buck when it comes to the welder being qualified to weld all positions with only 2 plate tests.