TIG Welding Stainless and Common Mistakes

- HOME

- TIG WELDING

- Tig Welding Stainless

scroll down for videos on how to tig weld stainless

Watch the latest welding videos at Weldmonger.com

Common Mistakes to Avoid When TIG Welding Stainless

TIG welding stainless steel demands, good gas coverage, cleanliness, and attention to detail.

Stainless Steel is used primarily for its corrosion resistance.

But bad welding procedures and techniques and ruin the stainless properties.

This article breaks down the most common errors in stainless TIG welding—and how to avoid them.

1. Inadequate Shielding Gas Coverage

The Mistake: The mistake is two fold and affects both front side and penetration side on full penetration welds. Not giving attention to gas coverage on both sides of the weld can lead to excessive weld discoloration, porosity, or sugaring on the back side.

How to Avoid It:

- Use 100% argon at the correct flow rate (2-3 CFH per cup size).

- Always use a gas lens and a large enough cup (#8 or bigger for open joints).

- Ensure the gas post-flow runs for 10-15 seconds after arc stop.

- Check for leaks or drafts in your shop that might disturb shielding.

- Purge back side of full penetration welds or use copper or aluminum chill block backing

2. Overheating the Weld

The Mistake: Excessive heat causes warping, and dark oxidation colors like grey and black. It also reduces corrosion resistance.

How to Avoid It:

- Use adequate amperage and fast enough travel speed and control heat with a foot pedal.

- Use pulse TIG settings for thin materials.

- Keep arc length short and move steadily.

- Chill bars or backing plates can help pull away excess heat on thin workpieces.

3. Skipping Proper Cleaning

The Mistake: surface contamination from tape residue or shop dust causes problems.

How to Avoid It:

- Wipe the weld zone with acetone before welding.

- Use a dedicated stainless steel wire brush—never one used on carbon steel.

- Clean filler rods with acetone as well—oils from handling can cause issues.

4. Using the Wrong Filler Metal

The Mistake: Using an incorrect filler metal can lead to cracking, reduced corrosion resistance, or weld failure.

How to Avoid It:

- Match filler metal to base material: ER308L for 304 stainless, ER316L for 316 stainless, 347 for 321 stainless , ER309L for stainless-to-carbon welds.

- Use low-carbon versions (L-grade) to reduce carbide precipitation and corrosion in the heat-affected zone.

- Keep work area clean and organized and make sure only the proper filler rods are within reach.

- One size smaller filler rod often works better for tig welding stainless steel

5. Poor Torch Angle or Arc Length

The Mistake: A steep torch angle or long arc length results in filler wire balling up from puddle and uneven welds.

How to Avoid It:

- Hold the torch at a 10–15° push angle.

- Keep the arc length tight—no more than 1/8". (Rule of thumb is diameter of electrode or slightly less)

- Use a sharp, consistent tungsten tip for better arc control.

6. Neglecting the Back Side of the Weld

The Mistake: Ignoring backpurging or not protecting the root side leads to sugaring, especially on pipe or sheet welds. Sugaring is a common term for excessive oxidation or granulation. It is a severe defect that causes weld failures and can contribute to bacteria growth inside a stainless pipe or tube.

How to Avoid It:

- Backpurge with argon on full-penetration welds.

- On certain jobs, an argon purge is mandatory. But on less critical sheet metal work, If you can’t purge, use backing bars or copper tooling to shield the back side.

- Maintain purge flow during and after welding.

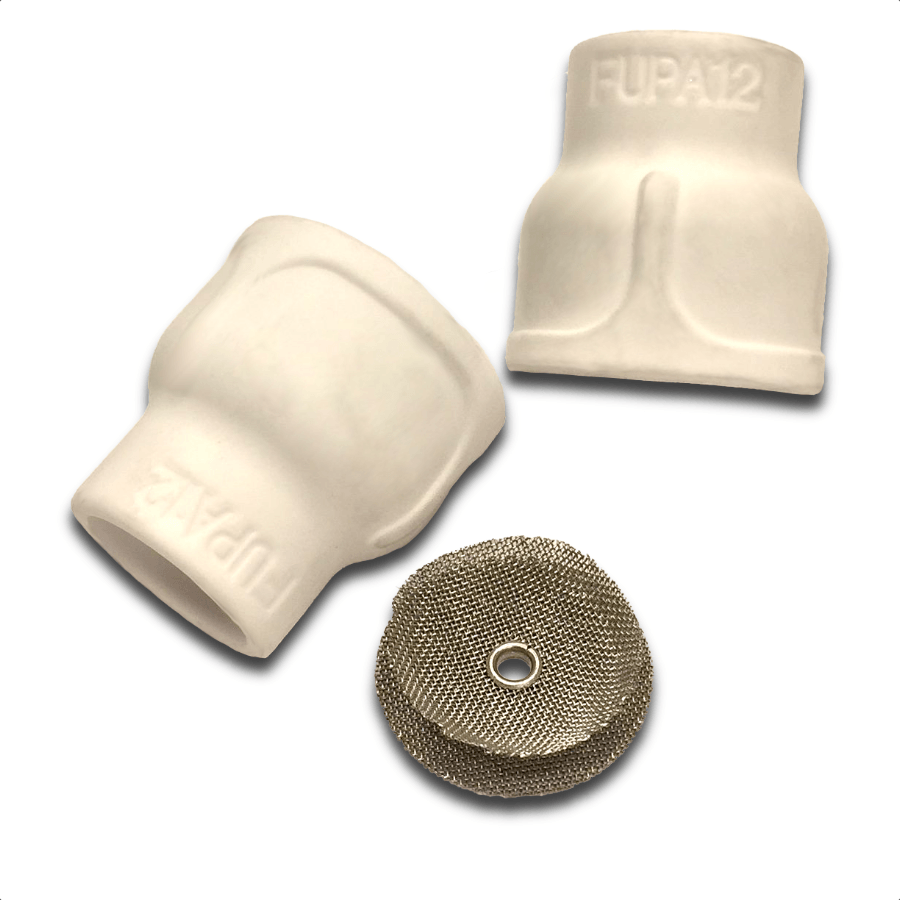

7. Not Using a Gas Lens

The Mistake: Relying on a standard collet body and small diameter cup reduces gas coverage and increases contamination risk.

How to Avoid It:

- Install a gas lens kit—it improves gas distribution and allows longer tungsten stick-out.

- Great for open-root welds and awkward angles where shielding is critical.

- Furick cups #10 and larger are extremely helpful for tig welding stainless steels

8. Ignoring Post-Weld Cleaning

The Mistake: Leaving heat tint or oxidation on stainless affects corrosion resistance and can fail inspection.

How to Avoid It:

- Brush only with stainless-specific tools.

- Use a weld cleaner (electrochemical, mechanical, or pickling paste) to remove heat tint.

- Rinse thoroughly and dry the work after cleaning.

9. Contaminated Tungsten

The Mistake: Dipping the tungsten into the weld pool or filler causes arc instability and dirty welds.

How to Avoid It:

- Keep your tungsten sharp and free of contamination.

- Regrind after contamination—don’t just continue welding.

- Use a dedicated grinding wheel or belt sander for tungsten only.

- Take time to sharpen a bunch of tungsten ahead of time

10. Welding in a Drafty Area

The Mistake: Even a small breeze can blow your shielding gas away and ruin a weld.

How to Avoid It:

- Use welding screens to block airflow.

- Shield the joint with larger cups or trailing shields.

- If you’re outdoors, increase CFH slightly in addition to using wind screens

- HOME

- TIG WELDING

- Tig Welding Stainless

click here to learn more about the Furick ceramic 12 cup

click here to learn more about the Furick ceramic 12 cup

Back Purging

When a full penetration stainless steel TIG weld is not back purged, several negative things can occur, compromising the weld quality and integrity.

more videos on how to tig weld stainless steel

best tungsten practices for stainless steel

stainless steel outside corner joint 16 ga