TIG Welding

Tungsten Types, Sizes, Applications

- HOME

- TIG WELDING

- Tig Welding Tungsten

Tungsten Diameter Tips

Some welders keep a 1/8" tungsten in their torch and use it for everything.

Others prefer a smaller tungsten because its cheaper, easy and quicker to sharpen, and makes for less wear and tear on a diamond wheel if you are using a tungsten grinder.

Mostly, it depends on what you are doing.

We have tungsten Holders with Color coded bands

at weldmonger.com

We put together this tungsten bundle because 3/32" is the most versatile and most commonly used tungsten but you still need a few 1/16" and 1/8"..

you know what I mean???

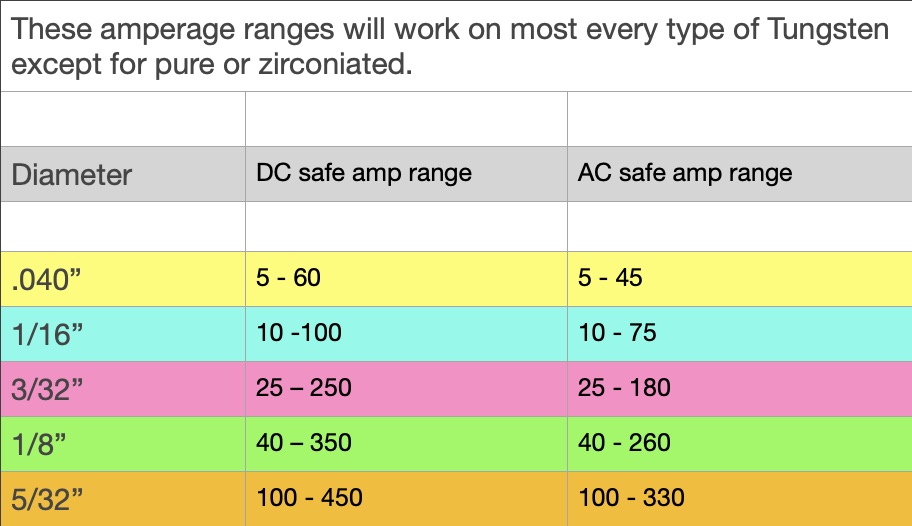

If you have every looked for a chart on the amperage ranges for different diameter tungsten electrodes, you might be as shocked as I was to see the maximum amperage for 1/16" tungsten at 150 amps.

The chart below lists a much more reasonable amperage range.

It used to be there were only two main choices for tungsten electrodes.

Either pure tungsten for Aluminum or 2% thoriated for DC tig welding of carbon, stainless steels and everything else.

Things have changed.

Pure, Zirconiated,2% thoriated, 2% Ceriated, 2% lanthanated, 1.5% lanthanated, E3, LayZr, and other Rare earth mixes and just some of the choices.

In addition to all the types of tungsten , there are multiple types of tig welding machines (transformer vs inverter) and all kinds of advanced TIG settings like AC frequency settings, AC balance, high speed pulse settings and even amplitude or offset AC settings.

Choosing the right tungsten electrode depends on the specific requirements of the welding task, the materials being welded, and even other considerations like the type of welding machine used.

There is no single tungsten type that is the absolute best tungsten for every single situation.

For example, 2% Ceriated might stay sharp longer on DC than 2% lanthanated, but ceriated does not carry high current well on AC.

Let's take a look at the pros and cons of the most popular tungsten types.

Let's start off by saying that pure tungsten is not the best choice for TIG welding aluminum except for older transformer design TIG welding machines and for very specific applications.

Pure tungsten balls evenly but just does not carry enough amperage for a given diameter.

If you really like the spherical ball that you get with pure tungsten, zirconiated tungsten will ball the same and carries a good bit more amperage than pure.

For the newer inverter design TIG welders , there are lots of better choices than pure or zirconiated.

- 2% Thoriated: is still one of the very best for high-current DC welding with excellent arc starts, but has health and environmental concerns due to its slight radioactivity. 2% thoriated does not ball evenly and can develop weird nodules and a mishaped tip when used with AC on aluminum.

- 2% Lanthanated: this is my personal all purpose tungsten because it Offers versatility, stability, and safety, making it a good all-around choice.

Another benefit to 2% lanthanated is that it simplifies things if you want to settle on one single type of tungsten electrode.

-2% Ceriated

Versatile Performance:Suitable for Low-Amperage Welding: Excellent for welding at low current settings, making it ideal for thin materials and delicate work.Effective for AC and DC Welding: Can be used for both AC and DC welding, providing flexibility in various applications, including aluminum (AC) and steel (DC) .

Stays sharp on DC but Works better at low to mid range amperage on AC.

Not Ideal for High-Amperage Welding: While excellent at low amperages, it is less effective at high current settings, which can limit its use in heavy-duty applications

- LayZr: Known for enhanced performance and long lifespan and really good restarts. Great performance on both AC and DC at mid range amps, but may be more costly and less available than more popular tungsten types.

- E3 (Purple): Provides versatility, stability, and safety, making it a strong contender for general use, despite being slightly more expensive. E3 is very similar to LayZr and performs pretty much the same.

In my opinion, the primeweld 225 is one of the best choices in affordable tig welders.

The problem with most other really affordable tig welders is usually the foot pedal and the torch are just bad and clunky.

Primeweld went to extra expense to include genuine ck torches with superflex hoses along with a smooth SSC style foot pedal.

They also have a responsive primeweld equipment users group on facebook and also have demonstrated great customer support

Watch some primeweld videos and you will see what I mean.