Can you Weld 2024 Aluminum?

- HOME

- TIG WELDING ALUMINUM

- How to Tig Aluminum

- Weld 2024 Aluminum

TIG Welding Aluminum

If you look at aluminum filler metal charts, you might notice that 2024 is not usually listed among all the other weldable aluminum alloys.

And if 2024 is not even listed, you can assume it's not recommended for welding.

I remember a time when I would see 2024 aluminum listed on filler metal charts along with 4145 filler rod as the best filler rod choice...but it was listed with a footnote of "not readily weldable" or "difficult to weld" or something like that.

And then one day, I noticed it was not even listed on aluminum filler metal charts.

I think liability is the factor. None of the filler rod companies want the liability of recommending a filler rod for 2024.

So the question is ..Can you weld 2024?

The short answer is yes.

But just because you can, does not mean you should.

At least not for anything really important.

For any application where someone might get injured if the weldment fails, then you should not attempt to weld 2024 aluminum.

Tree stands, ladders, and lifting devices are just a few examples where 2024 aluminum should definitely NOT be welded.

But there are many scenarios where there is very low stress and where there is no real risk.

I liken it to welding free machining 303 stainless or 12L14 free machining steel.

Neither 303 stainless nor 12L14 are recommended for welding but both are frequently welded for very low stress applications like simple boss inserts that hold a bearing where something turns at a low rpm, or small axles on low rpm machinery.

The weld metal, fusion zone, and even the heat affected zone (HAZ) on 2024 weldments will most likely develop micro cracks and even delayed stress corrosion cracking.

All that makes for an unpredictable failure on highly stressed components.

But for certain products, that might actually not be a problem.

For example, I once fabricated a tool tote tray from 2024 t4 aluminum and welded all the corner joints along with the handle using 4145 aluminum filler rod.

But it was a tote tray.

Welds on a tool tote tray are not exactly what I could consider critical.

I can think of a few other low stress non critical applications like...

What about a silk screen frame made from 2024 angle?

An injection mold machined from 2024 that has a ding or damaged pry ear.

Certain 2024 parts can be welded...But You need to be discerning.

A good question to ask yourself is this...

If this part fails, would it likely hurt someone, or damage something?

IF the answer is yes, then it is probably wise to not weld it

What about welding other unknown aluminum?

There is no simple way to distinguish between aluminum alloys without sending it to a metallurgical lab for some type of spectrometer test.

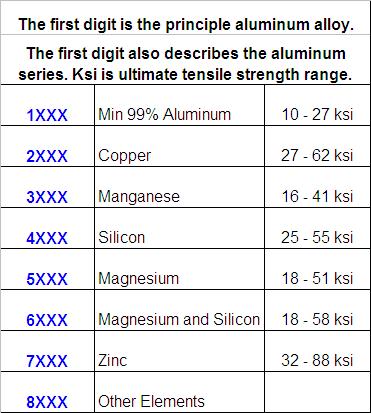

Sure there are some chemical test kits that can distinguish 2000 series from 7000 series but are not very effective at identifying something like 2024 from 2319 aluminum.

So the bottom line is, don't weld aluminum that you are not sure of.

And if you are asked to repair an aluminum component that does not have any welds on it and is held together using only rivets or other mechanical fasteners......There is a reason rivets were used.

I wouldn't weld it. Not worth the risk.