3G 7018 Welding Test Tips using 1/8" AND 5/32" Electrodes

3g 7018 1/8" plate test

A 3g 7018 plate structural welding test is a common test for ironworkers and other welders who need to be certified to AWS standards.

This 3g 7018 weld test is often done using 1/8" 7018 electrodes but occasionally the test is given where a 5/32" is required all the way out.

5/32" is slightly more difficult to use but not too bad if your amperage settings, arc length, and technique are good,

Fit up

The AWS D1.1 specifications for a 3/8" thick 3G test with a 1/4" thick backing strip call for 22.5 deg beveled plates and a 1/4" gap +- 1/16".

With a bigger electrode like 5/32" using all the tolerance and gapping to 5/16" helps.

5/32" 7018 needs a bigger gap in order to be able hold a tight enough arc for the root pass.

And although the SMAW process does a good job of penetration through hot rolled mill scale, best practice is to remove mill scale from all welded areas and also about 1/4" past where any weld toe.

Amperage settings for 3g 7018 5/32"

I would recommend getting the Lincoln Electric Consumable Catalog for anyone ...whether you like Lincoln products or not.

there is a wealth of information in this catalog that can help you out when you are in doubt of an amperage setting for a certain size and type electrode you might not use frequently enough to know it.

The Lincoln Consumable catalog is also great for flux core and mig settings.

Lincoln settings wont always be ideal for other brands of electrodes but its way better than playing blind archery. it will get you really close and save you time.

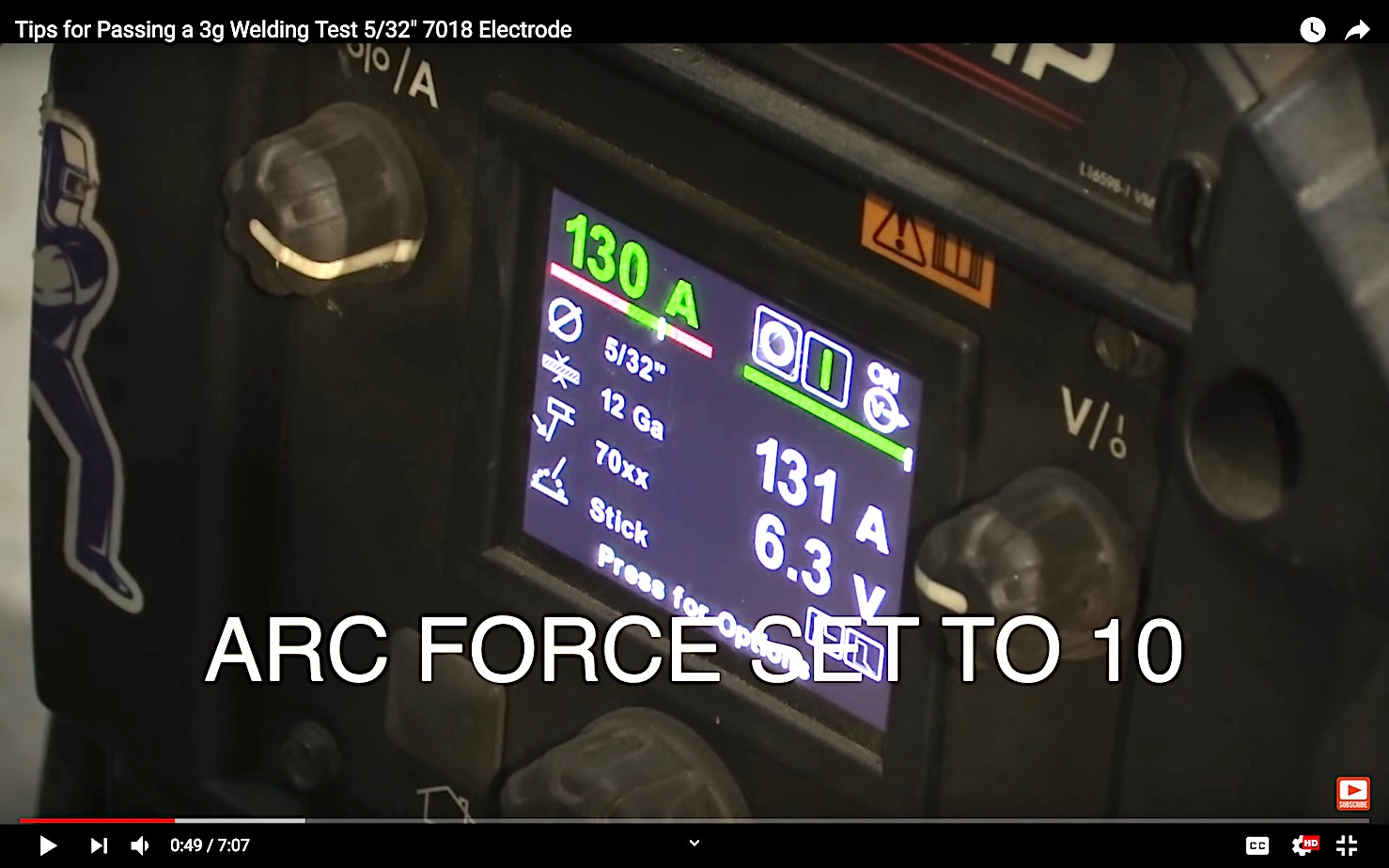

The catalog listed the amperage range for 5/32" 7018 at 130-210 amps.

Since we were welding vertical uphill, we knew we would be at the low end of the amperage range at 130 amps.

The machine we used for this 3G 7018 test was a Lincoln Powermig 210mp and it has a function called "Arc Force" also known as "DIG".

We set the arc force setting all the way to 10.

Arc force function on the 210mp and other machines senses the drop in voltage when the arc gap gets tight and bumps up the amperage to avoid sticking the electrode.

So we figured that would be a good idea and would allow us to run the 5/32" 7018 at only 130 amps without sticking when the arc got tight.

130 amps is only slightly hotter than what would normally be used for a 1/8" 7018 but trying to run hotter posed more potential for undercut.

Root

At 130 amps with arc force set to maximum and using a slight push angle with a tight arc, Andrew used a slight manipulation to work the arc around to avoid a convex bead.

Only one restart was needed near the end.

Fill and cap

Stringer beads are often a requirement on a AWS D1.1 weld test.

Not necessarily required by the code itself, but left up to the engineering authority.

No matter, if stringers are required by the WPS, you have to use stringers.

The goal on the fill passes is to allow for a cover pass that meets the 1/8" maximum height requirement in AWS D1.1 testing specs.

That can be a challenge with 5/32" 7018 electrodes.

This is another reason why we ran at the low end of the amperage range for 5/32" 7018.

More videos on welding with 5/32" 7018

Vertical 3F tee joint using 5/32"m 7018 electrode

Overhead Fillet Weld tee joint 4f with 5/32" 7018

Overhead Tube to plate with 5/32" 7018