7018 Tee Joint 2F

visit the store to check out gloves and more

This page is about Stick welding a 7018 Tee Joint in 2F horizontal position.

The amperage range listed on the Esab 7018 pack was 110-140 amps.

there is a rule of thumb that says "one amp per one thousandths".

a 1/8" rod is 125 thousandths so 125 amps would be a good starting point. ( for flat and horizontal welding)

but every brand runs a little different.

So I went with 130 amps and left it there for all three weld passes.

CLAMS for Stick Welding

There is an Acronym that helps to remember the essential things that matter when stick welding....or any welding process for that matter.

If you have already read this on another page, then just scroll to the next topic.

C stands for Current. that means Voltage, Amperage, and polarity.

7018 is almost always used with DCEP Direct Current Electrode Positive aka Reverse polarity.

It will weld ok with AC on some machines and will also weld using DCEN but it is not recommended

L stands for Length of Arc. the length of the Arc affects voltage and for the most part, a tight arc length works best.

What is a tight arc length? with a 7018 you cant really see how long the arc length is because the core wire melts off to where the core is recessed so even when you think the arc length is zero, its probably not.

A is for Angle of Electrode. Electrode angle is pretty forgiving as long as the arc length is tight. For a 2F horizontal Tee, I used a slight drag pull angle of around 5-10 degrees. Sometimes even 90 degrees straight in.

M is for manipulation of electrode. I didnt use much manipulation for this weld but sometimes I do use a series of cursive e motions

S is for Speed of Travel. Travel speed for a 7018 1/8" electrode varies but for this weld is was approx 6 inches per minute.

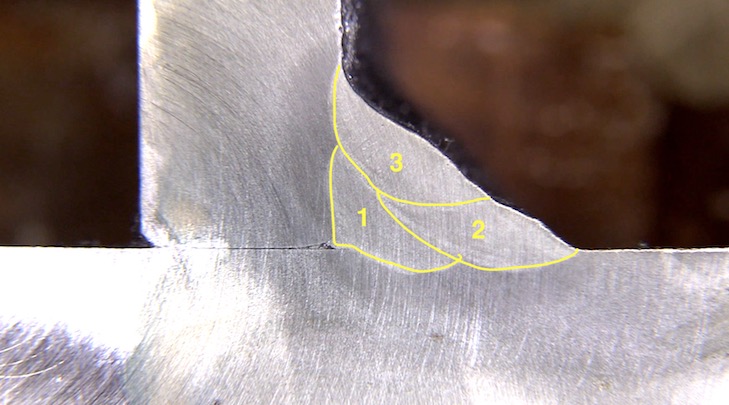

Cut&Etch test

The Cut and Etch macro test can really help when you are trying to develop a welding procedure or even just verifying settings.

I like to say that one single cut and etch test is worth more than 100 opinions.

When you cut a section, polish, and etch, you can often see each individual weld pass along with depth of penetration or lack of penetration.

Granted, its only one slice out of the weld, but it can give you some quick and very valuable information

Can you Weld this same joint Overhead at same amps?

Watch overhead 7018 at 130 amps video