How to TIG Weld Steel outside corner joints

- HOME

- TIG WELDING

- How to Tig Weld

TIG Welding Outside Corner Joint

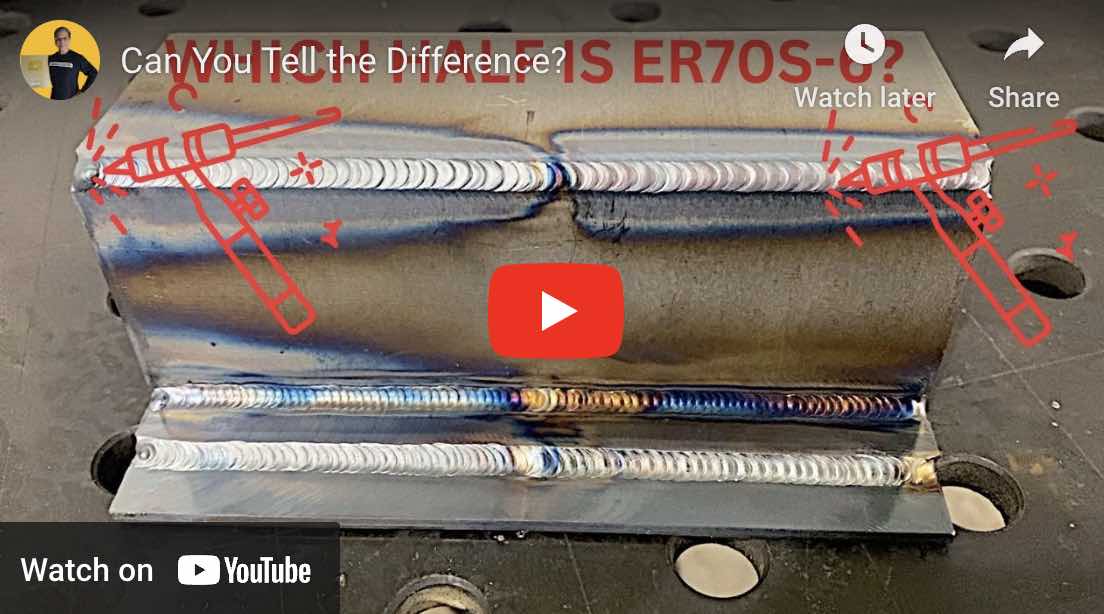

Corner, Lap, and Tee Joint video comparing TIG rods

Practical application for outside corner joint

In the third video, we show how to tig weld steel outside corner joints using 16 ga cold rolled steel. Also known as CRS.

In this weekly video, I am fabricating a small air box that will weld to the side of a cutting table so I can connect a Miller fume extractor snout to it to suck the fumes downward.

I wont get into the cutting table much today. Instead, just focusing on the welding.

| Base Metal | 1010-1020 cold rolled steel |

| Tungsten Electrode | 3/32" 2% lanthanated |

| electrode stickout | 3/8" |

| filler rod | 1/16" er70s-2 |

| amperage | 55-65 |

| shielding gas | argon |

| cup size and flow rate | 7 gas lens 15-20 cfh |

| postflow | 10 sec |

I framed up a 1 inch angle box to begin with to make it stiffer. This is really a job for a sheet metal brake but I figure a lot of folks out there dont have one and honestly, this was more fun than bending the metal to avoid weld joints.

An oustide corner joint is one of the easier joints to weld and very often, in sheet metal thickness, does not even need filler rod.

But for the sake of instruction and a better how to tig weld steel video, I used filler rod except for one small clip.

I used 1/16" diameter rod Er70s-2

I experimented with a little 309 stainless in one of the clips in the video...can you tell which one?

here's a hint...its the bead where I got too hot, and then tapered off on the very end leaving the rod in the puddle.

Outside corner joints are a quick way to make a box. Sometimes its much quicker than bending the metal on a sheet metal brake.

See more videos on how to tig weld steel

If you are still using the standard TIG cups and hardware that came with your machine or TIG torch, I can just about guarantee you will get better results if you upgrade to a weldmonger® stubby gas lens kit.