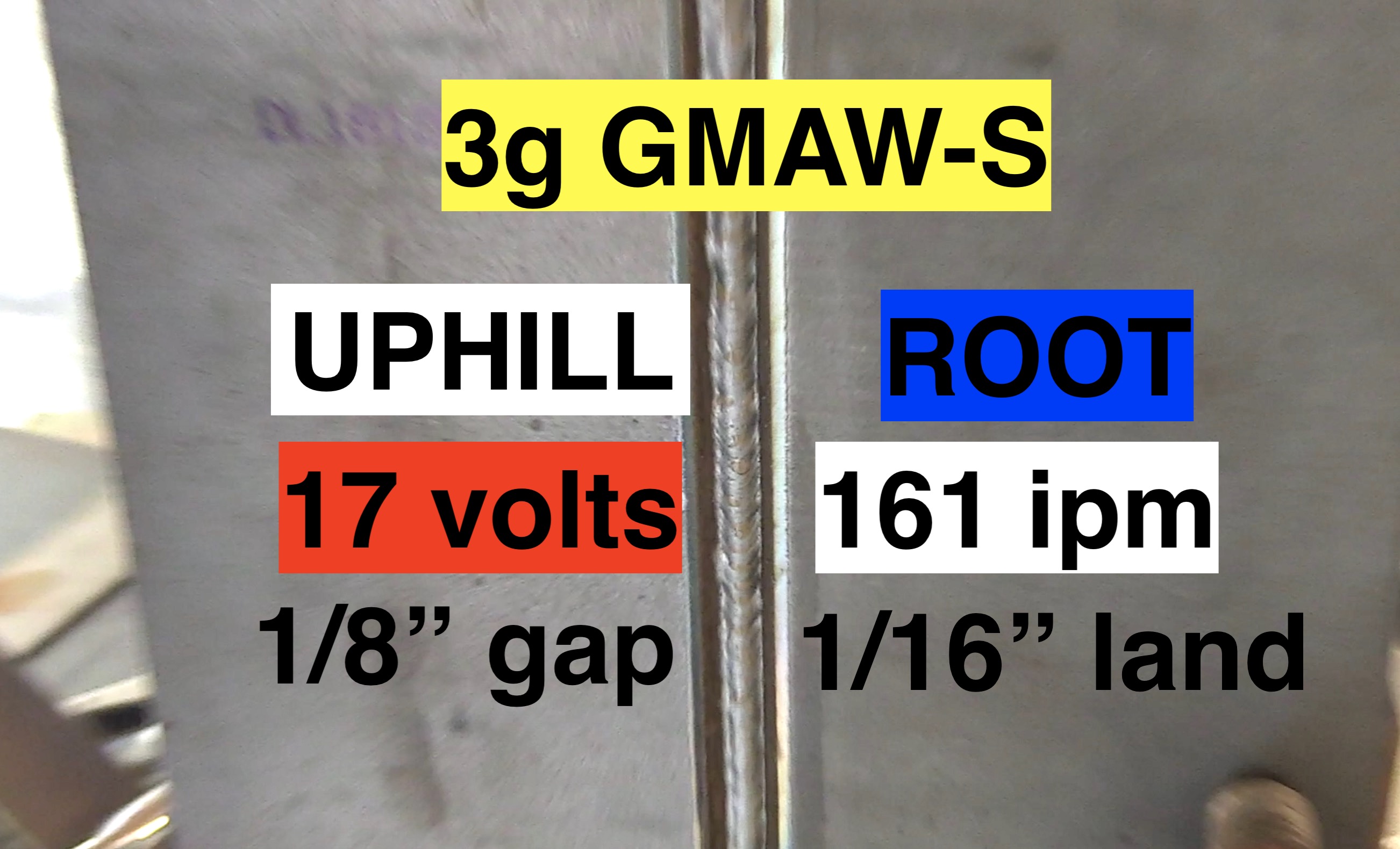

Mig Welding Carbon Steel 3/8" 3g plate test open root uphill settings

- HOME

- WELDER SETTINGS

- Mig Welder Settings

- Mig Welding Carbon Steel 3/8"

scroll down for settings

WELD PROCESS = GMAW, SHORT CIRCUIT MIG, GAS METAL ARC, BARE WIRE MIG

METAL TYPE = CARBON STEEL, COLD ROLLED STEEL, A36

THICKNESS = 3/8” with 30 degree bevel

WELD TYPE = uphill root pass for open butt Groove weld

JOINT TYPE =Butt Joint root pass

POSITION = 3g vertical uphill root with 3/32” - 1/8” gap and slight land around 1/16"

VOLTS = 17 volts

WIRE SPEED =161 IPM

WIRE SIZE = .035"

POLARITY = DCEP

GAS FLOW = 20-25 CFH C25 GAS

CTWD = 3/8”-1/2"

FILLER METAL = ER70S6

ADDITIONAL SETTINGS =

TIPS:A relatively short stickout aka contact to work distance CTWD of 3/8” to 1/2" makes a big difference.

The technique shown keeps arc on the leading edge of the puddle.

stay on front of puddle and use just enough side to side motion to control the puddle and avoid shooting wire thru the gap.