TIG Welding 304L Stainless Steel

- HOME

- Tig Welding Stainless

- Tig Welding Stainless Steel

- Tig Welding 304L Stainless Steel

Introduction to 304L Stainless Steel

What is Stainless Steel?

Stainless steel isn't just a shiny metal—it’s a marvel of modern metallurgy. In essence, stainless steel is an iron based steel alloy with a minimum of 10.5% chromium content by mass.

There are multiple types of stainless steel, each tailored for specific uses. They’re broadly categorized into austenitic, ferritic, martensitic, duplex, and precipitation-hardening steels.

The most commonly used types belong to the austenitic family, with grades like 304 and 316 being the most commonly welded grades of stainless.

Within that family lies 304L—often referred to as the low-carbon version of the more standard 304 grade.

Key Properties That Make Stainless Steel Popular

Stainless steel is highly favored for its corrosion resistance, high tensile strength, and clean appearance. But its popularity doesn’t just stop there. It’s also:

- Easy to clean and sterilize

- Resistant to heat and chemicals

- Long-lasting with minimal maintenance

- recyclable

This suite of benefits makes it ideal for industries ranging from healthcare to construction, food processing to aerospace.

Among all stainless steel variants that are welded, 304L is the most widely used. Let’s explore why.

Understanding the 304L Stainless Steel Grade

What Does the “304L” Stand For?

Let’s break down the name “304L.” The number 304 identifies the basic grade, which belongs to the austenitic family. The “L” stands for “low carbon.” This seemingly small difference has a major impact. By reducing the carbon content (typically to a maximum of 0.03%), 304L minimizes the risk of carbide precipitation during welding...at least compared to regular 304 stainless. That means better weldability and less susceptibility to corrosion in the heat-affected zones of welds.

In simpler terms? If you need stainless steel that can be welded without cracking or losing its corrosion resistance, 304L is often a good choice.

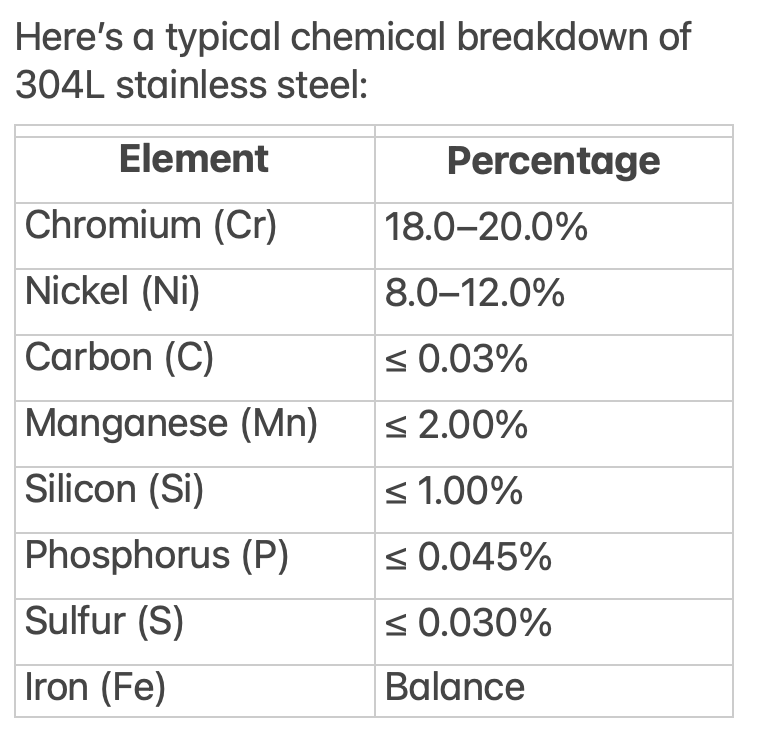

Chemical Composition and Structure

You might notice that the chromium is between 18 and 20% and the nickel is between 8 and 12%.

this is why 304L stainless is often referred to as 18-8 stainless steel.

Filler metal for TIG welding 304L stainless

ER308L is the recommended filler rod for TIG welding 304L stainless steel.

Here is a handy stainless filler metal chart for many different grades of stainless steels

Why 304L Stainless Steel Is So Widely Used

Corrosion Resistance

One of the most significant reasons 304L is the go-to stainless steel grade is its excellent resistance to a wide range of atmospheric environments and many corrosive media. In fact, 304L’s low carbon content offers better resistance to intergranular corrosion—a type of degradation that occurs in the grain boundaries of the material after exposure to high temperatures, especially during welding.

Unlike higher carbon grades, 304L doesn’t form chromium carbides easily, which can rob the alloy of its corrosion-fighting chromium. That’s why industries trust 304L for structures that must endure humid, chemical-rich, or variable environments.

Weldability and Formability

Weldability is where 304L truly shines. Thanks to its low carbon content, 304L can be welded without any need for post-weld heat treatment. That’s a big deal in manufacturing and construction, where time and cost savings are critical. It’s also easily formable, which makes it suitable for everything from tubing to complex shapes used in appliances or architectural designs.

If you’ve ever seen sleek railings, kitchen counters, or escalator panels, chances are, 304L was involved. It bends, molds, and shapes without losing its strength—a metalworker’s dream.

Availability and Cost-Effectiveness

Here’s the clincher: 304L stainless steel is both abundant and affordable. Because it doesn’t require high levels of expensive elements like molybdenum (as seen in 316L), it’s easier and cheaper to produce. Combine that with its widespread application potential, and you’ve got a material that’s not only efficient but also economical.

304L is also readily available globally, which reduces lead times and simplifies sourcing for manufacturers and contractors. It’s the stainless steel you can depend on without blowing your budget.

Limitations of 304L Stainless Steel

Just because 304L works great in general-purpose applications doesn’t mean it’s the right fit for every job. Using it in the wrong conditions—like marine environments or high-heat applications—can lead to premature failure, safety risks, and expensive replacements. Knowing these limitations helps engineers, builders, and designers make smarter, safer decisions.

Chemical Limitations

Absence of Molybdenum and Its Impact

One of the biggest weaknesses of 304L stainless steel is that it does not contain molybdenum, unlike its more corrosion-resistant cousin, 316L. Molybdenum enhances resistance to chloride-induced pitting and crevice corrosion. Without it, 304L becomes vulnerable in environments with high salt or acidic content.

Vulnerability to Chloride-Induced Corrosion

Chloride ions—commonly found in seawater, de-icing salts, and certain cleaning agents—can rapidly degrade 304L. It’s particularly susceptible to pitting corrosion, where small holes form on the surface and deepen over time. This makes 304L unsuitable for use in coastal areas, swimming pools, or chemical plants that deal with chloride-rich environments.

Limited High-Temperature Strength

Though 304L is considered “heat resistant” to a certain degree, its performance drops off sharply at elevated temperatures. In applications above 800°F (425°C), 304L loses strength and becomes prone to scaling. This can compromise both safety and structural integrity in components like exhaust manifolds or heat exchangers.

Risk of Sensitization Under Heat

When exposed to high temperatures for prolonged periods, 304L can suffer from sensitization—a condition where chromium carbides form along grain boundaries, reducing the alloy's corrosion resistance. Although the low carbon content helps reduce this risk compared to standard 304, it doesn't eliminate it entirely, especially during improper welding cycles like not observing interpass temperature requirements.

You see this a lot on multiple pass welds on stainless steel pipe joints where hurrying to get the job done can overheat the stainless and keep it in a sensitization heat range for too long.

Not Suitable for Marine Applications

If you’re planning to use 304L stainless steel on a boat, pier, or anything near the ocean—think again. The salt-laden air and water will corrode it quickly. It simply can’t withstand the aggressive, chloride-heavy conditions of marine environments. For such applications, 316L or duplex stainless steels are much better options.

Poor Performance in Acidic and Harsh Chemical Settings

304L performs ok in mildly acidic conditions, but it struggles in environments where sulfuric, hydrochloric, or nitric acids are present. These chemicals break down the passive chromium oxide layer, exposing the steel to rapid degradation. In chemical processing plants or industrial cleaners, 304L can become a liability.

When Is 316L Stainless Preferred Over 304L?

If your application involves seawater, de-icing salts, or acidic conditions (like sulfuric, hydrochloric, or acetic acid), 316L is the way to go. It’s commonly used in environments where corrosion isn’t just a possibility—it’s inevitable. See article on TIG welding 316L stainless here