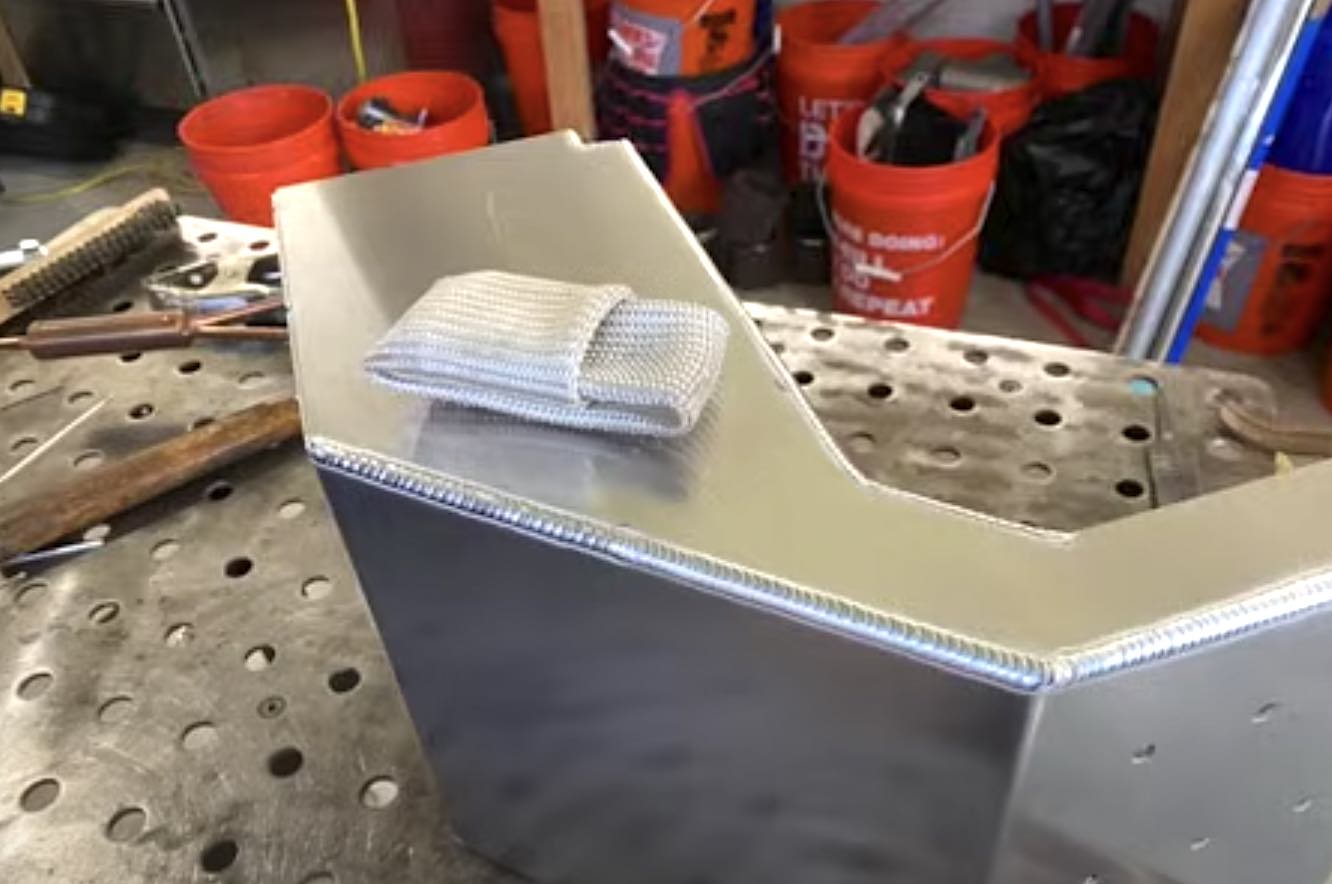

TIG Welding 5052 Aluminum

Details for TIG welding 5052 aluminum Dog feeder

Material is .090" thick 5052 aluminum

Filler metal is 3/32" 5356

2% lanthanated tungsten 3/32" tapered

#5 standard ceramic cup with 15-20 cfh argon

Amperage was set to 180 on machine but pedal pumping technique was used

- HOME

- TIG WELDING ALUMINUM

- How to Tig Aluminum

- Tig Welding 5052 Aluminum

My good friend and welderskills instructor Brad Goodman dropped by for a visit and brought some pieces from one of his dog feeders.

Brad put on a clinic on how to pulse with the foot pedal.

Here is another video of Brad Goodman showing how he uses the pedal pump tig welding technique to achieve that "stack of dimes" look

TIG welding 5052 aluminum and pulsing with the foot pedal

Pulsing with the foot pedal has become a very common tig welding technique amongst motorsports welders and also in a few other industries where strict adherence to welding procedures is not required.

After watching my friend Brad Goodman use this technique on aluminum, chromoly, and stainless steels, I understand some of the benefits.

Pulsing with the pedal really does help to control heat input.

We all know that when tig welding aluminum, we tend to use more amperage on a cold part and let off the foot pedal when the part starts to heat up.

We also tend to adjust our travel speed according to how the part heats up.

Pulsing with the foot pedal tends to even things out and lessens all those fluctuations and so the bead looks more the same from start to finish.

Another big benefit to pulsing with the foot pedal is making restarts.

Because of the distinct stack of dimes look, restarts on aluminum are less noticeable and seem to blend in better.

And of course, when you are welding and need to make a turn or adjust your torch angle, pulsing manually with the pedal allows you to pulse whenever you are ready instead of being locked into to automatic pulse settings.

What is the best filler metal to use for tig welding 5052?

5356 is usually the best choice for tig welding 5052 aluminum.

When 4043 is used to weld 5052 aluminum, it can set up some unfavorable mechanisms in the microstructure. Silicon and Magnesium mixing in the wrong ratios can cause cracking issues.

5356 filler is also often used for welding 6061 aluminum when it will be anodized after welding in order to provide a good color after anodizing.