TIG Welding Cast Aluminum, Cleaning Action, and 4047 Filler rod

- HOME

- TIG WELDING ALUMINUM

- How to Tig Aluminum

- Tig Welding Cast Aluminum

When you need to TIG weld Dirty aluminum or Cast Aluminum, let the cleaning action work for you.

What do I mean by that?

I mean instead of puddling right away...(something you can usually do on brand new clean aluminum)...

...let the cleaning action clean away some impurities first.

in order to get the most out of the cleaning action, do these two things...

- set the AC balance for more cleaning

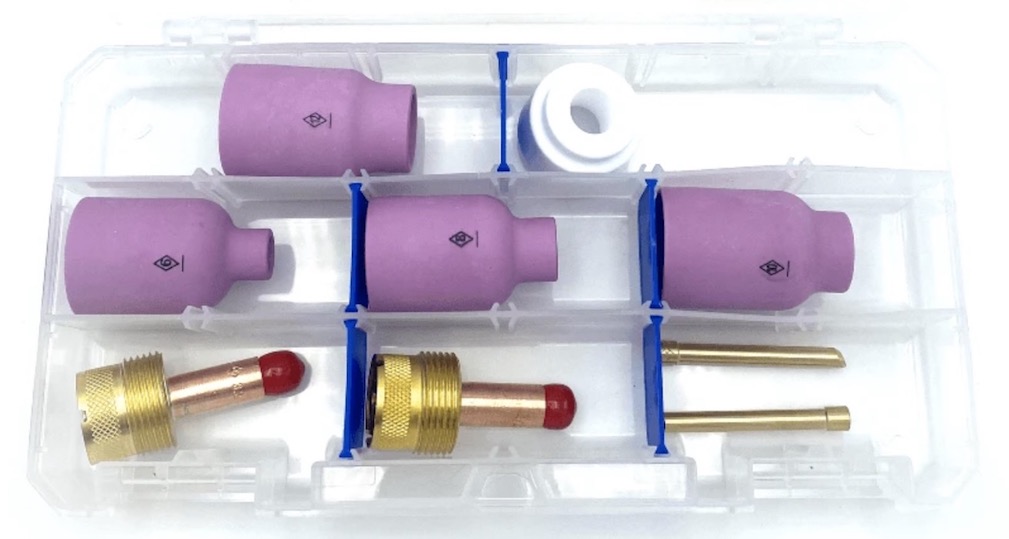

- use a gas lens with a #8 cup

What does AC balance do for TIG welding cast aluminum?

Most Modern TIG welders have a setting called AC balance.

The AC balance setting allows you to adjust how much electrode positive cleaning action you get when welding aluminum on Alternating current.

Being able to adjust AC balance can be very helpful because sometimes we get to tig weld brand new clean aluminum...but sometimes we need to weld oxidized, dirty, or oil soaked cast aluminum.

Brand New aluminum usually welds fine with an AC balance setting of around 70% EN (30% EP).

But cast aluminum and dirty aluminum usually welds much better with more cleaning action and an AC balance setting of as low as 60% EN.(40%EP)

What does a Gas lens do?

A gas lens is designed to provide a more even flow of argon.

And since the cleaning action of the AC arc only goes where there is argon shielding, a larger path of argon makes for more cleaning action.

Don't misunderstand what I am saying here.

A gas lens is not always the best cup for every situation.

In fact, a standard #5 cup often works fine for thinner welds on new aluminum.

But for dirty aluminum, and for tig welding cast aluminum, a gas lens can definitely help you get a cleaner weld.

SETTINGS AND DETAILS

WELD PROCESS = TIG, GTAW, GAS TUNGSTEN ARC WELDING

METAL TYPE = ALUMINUM CASTING

THICKNESS = 1 INCH

WELD TYPE = BUILD UP BEADS

JOINT TYPE = BUILD UP

POSITION = FLAT

AMPERAGE =200 AMPS CONTROLLED WITH FOOT PEDAL

TUNGSTEN = 2% LANTHANATED, 1/8"

FILLER WIRE = 3/32” 4047

POLARITY = AC

GAS FLOW = 20 CFH argon

CUP SIZE = 8 GAS LENS

ADDITIONAL SETTINGS = AC BALANCE 35% CLEANING, AC FREQ 60HZ PRE FLOW = 1 SEC

POST FLOW = 10 SEC

NOTES AND TIPS: USE CLEANING ACTION TO BOIL OUT CONTAMINANTS BEFORE MELTING. THIS MIGHT NEED TO BE DONE SEVERAL TIMES FOLLOWED BY STAINLESS WIRE BRUSH OR CARBIDE BURR OR BOTH BEFORE PART IS CLEAN ENOUGH TO WELD

Aim for an arc length that is equal or less than the diameter of your tungsten electrode. Torch angle can be forgiving provided your arc length is tight.

Why its important to clean aluminum

Cleaning aluminum prior to TIG welding is important for several reasons:

- Removal of surface contaminants: Aluminum can accumulate various contaminants such as dirt, oil, grease, oxide layers, and other impurities. These contaminants can negatively affect the quality and integrity of the weld. By cleaning the aluminum surface, you ensure that these contaminants are removed, allowing for a cleaner and stronger weld.

- Prevention of porosity: Aluminum has a high affinity for oxygen, and when exposed to air, it rapidly forms an oxide layer. This oxide layer is known as aluminum oxide, which has a higher melting point than aluminum itself. If the oxide layer is not removed before welding, it can result in porosity in the weld. Cleaning the aluminum surface removes this oxide layer, reducing the risk of porosity and ensuring better fusion between the base metal and the filler material.

- Enhanced weld appearance: Welding on a clean surface helps achieve a visually appealing weld. Contaminants on the aluminum surface can lead to discoloration, spatter, and other aesthetic issues in the weld. By cleaning the aluminum, you improve the appearance of the weld and ensure a more professional finish.

- Improved weld quality and strength: Clean aluminum surfaces allow for better heat transfer and improved fusion between the base metal and the filler material. This leads to better welds. Contaminants can act as a barrier, hindering the flow of heat and compromising the integrity of the weld joint. By cleaning the aluminum, you create optimal conditions for a high-quality and strong weld.

To clean aluminum prior to TIG welding, common methods include using a stainless steel wire brush or a dedicated aluminum cleaning brush to mechanically remove contaminants, and using solvents or cleaners specifically designed for aluminum to remove oils and greases.