You just landed on the Best Web page for Practicing Aerospace Welding Tests

in simple short videos

scroll down for Aerospace Weld Test videos

Basic Stainless 1G aerospace welding test per D17.1 specs

note: these are practice videos using inexpensive metals intended to teach the fundamentals. aerospace test welds use more difficult to weld alloys like 15-7ph, inconel 718, and more.

go to main weld test page with videos on 6g pipe welding tests as well as 3g and 4g plate tests

Most Aerospace weld tests are done using some type of purge fixture.

If you have never taken a weld test like this, the video above will give you some good tips for how to position the pieces in the fixture, amperage and purge flow settings, along with clear arc shots and tips.

Basic Stainless 2f Tee joint aerospace welding test per D17.1 specs

Here are links to individual pages for Aerospace welding test videos on carbon steel, stainless steel, aluminum, and titanium.

2g carbon steel horizontal butt

1g stainless using abom fixture flat butt joint

1g titanium flat butt weld test .040"

2g titanium horizontal butt joint test .040"

3g titanium .040" butt joint vertical

1g aluminum flat butt joint .063"

3g aluminum vertical butt .063"

2f stainless tee joint fillet weld test

2f titanium tee joint fillet weld test

Generally speaking, a lot of aerospace welding tests consist of a butt joint and a tee joint for every different material qualification needed from the following groups of metals

- Carbon and low alloy steels - test metal is often 4130

- Iron based stainless steels - test is often 17-7ph

- Nickel alloys - test is often inconel 718

- Aluminum Alloys - test is often 6061 aluminum

- magnesium alloys - test is often AZ31B

- Titanium alloys - test is often 6AL4V

- Cobalt alloys - test is often Haynes 188

The tee joint in 2F position is often given using .032" thickness in order to achieve a broad thickness qualification.

Fillet tests can be difficult in thicknesses of .050 and thinner because you are trying to get complete fusion into the root of the joint while at the same time trying to avoid melting thru the back side.

The goal on this aerospace welding test is to achieve penetration into the root of the joint without melting through.

The AWS D17.1 specification provides some tolerance for melt thru but weld test supervisors all interpret it differently.

A lot of inspectors don't want to see any melt thru at all on thicknesses .063" and under

Aerospace Welding Test practice Tips

Aerospace welding tests don't always represent the actual welding task but the engineering authority can create a more limited qualification test.

In aerospace welding, qualification tests are required to prove that a welder can consistently produce welds that meet strict engineering and safety requirements. However, the standard coupon tests (like a butt joint in a specific thickness and alloy) don’t always match the exact tasks a welder will do on real aircraft or engine parts.

That’s why AWS D17.1 (the aerospace welding specification) gives the Engineering Authority some flexibility.

The Engineering Authority is the responsible individual or group (often a customer, design authority, or prime contractor) who ensures welding meets the design and performance requirements.

They can require standard code tests like groove weld and fillet weld tests, but they’re also allowed to design limited qualification tests that better reflect the actual production or repair work.

For example:

- A welder might normally only weld build up edge beads to restore dimensions on knife edge air seals . Instead of making them qualify on a butt joint plate, the Engineering Authority can specify a more limited test coupon (such as a scrapped part or even a mocked up part) that demonstrates the same skill set actually needed on the job.

In short:

- Standard tests like butt and tee joints provide a broad qualification that covers many situations but may actually be overkill. Conversely, standard butt and tee joint test joints might actually insufficient due to part thickness or configuration.

- Limited tests can be adopted by the Engineering Authority to match the actual production welds, reducing unnecessary testing while still ensuring welders are properly qualified for the exact work they’ll do.

I copied this excerpt from D17.1 from a post on the AWS forum

3.7.5 Special Applications. When none of the test welds described above are applicable to a given production weld, a special welder or welding operator qualification limited to the specific application may be achieved with a test weld consisting of the given production weld or a test weld representative of the given production weld.

4.4.4 Alternate Methods of Procedure Qualification. In lieu of 4.4.3, welding procedure

qualification may be accomplished by welding at least one procedure qualification test weldment

consisting of any of the following:

(1) A simulated weld joint sample.

(2) An actual part.

(3) An applicable qualification test weld.

(4) A special test weldment.

(a) Simulated service test weldment.

(b) Prototype structural special test weldments.

(c) Non-loaded special test weldments.

The Engineering Authority shall provide the test methods and acceptance criteria for the test weldments to be used when qualifying weld procedures.

4.4.5 Use of Existing Qualification. Alternatively, and in lieu of 4.4.2, an existing qualified

welding procedure may be accepted as equivalent to the requirement of this specification at the sole discretion of the Engineering Authority.

Why is this provision not used more?

2g aerospace welding test practice using Carbon steel

The Aerospace alloys most often used for weld certification tests are:

- 4130 chromoly

- 17-7 ph stainless ( ph stands for precipitation hardening)

- Inconel 718

- 6061 aluminum

- Az31B Magnesium

- 6AL4V Titanium

- Haynes 188 or L605

Some of these alloys are extremely expensive so it makes sense to get some practice on plain carbon steel before attempting to weld on the more expensive alloys listed.

Carbon steel is cheap practice metal but still provides good practice for aerospace welding tests.

Tips for passing a 1G aluminum aerospace welding test

Cleaning the sheared edge on butt joints is one of the most important steps in passing an aluminum aerospace weld test.

go to main weld test page with videos on 6g pipe welding tests as well as 3g and 4g plate tests

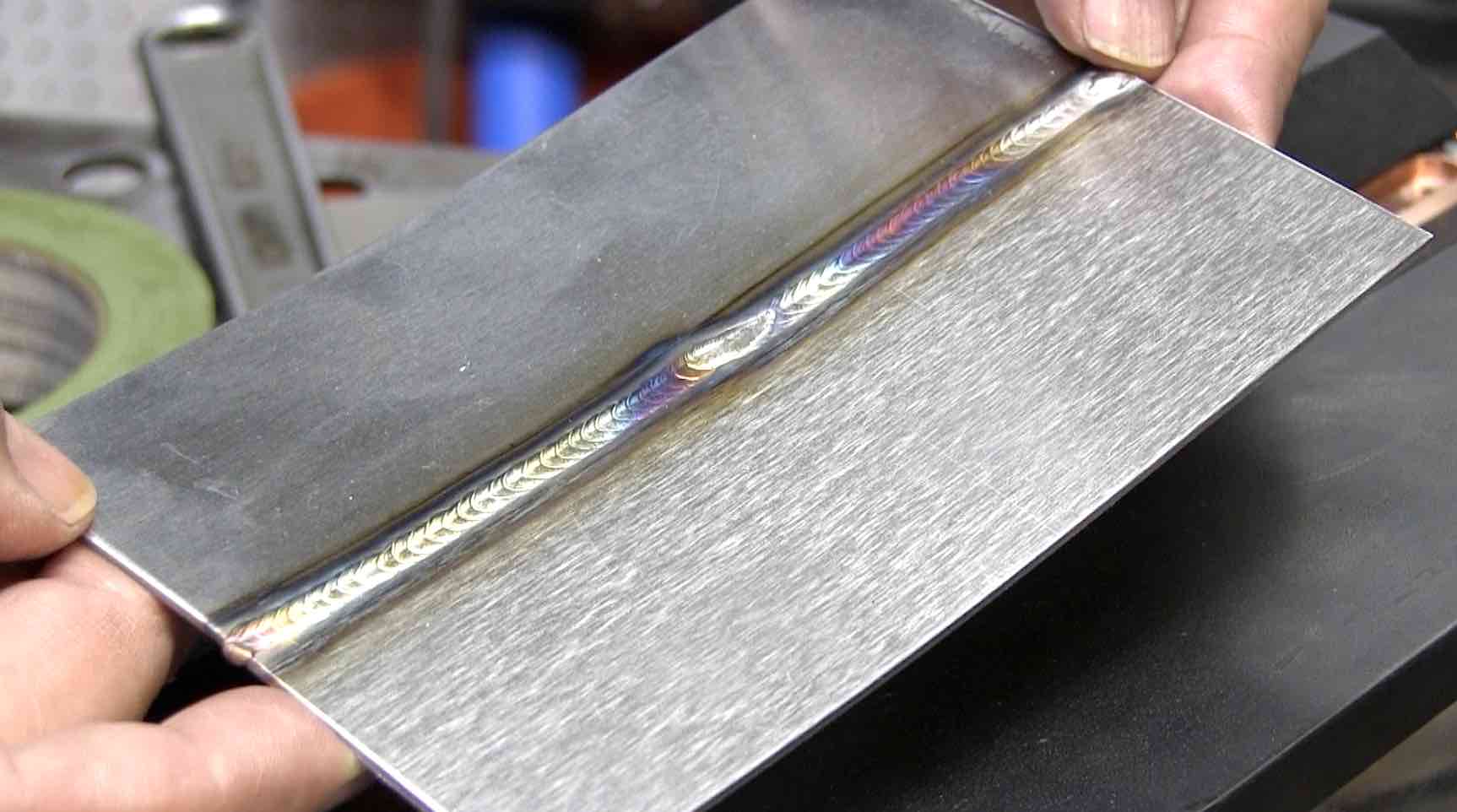

1G Titanium Aerospace Welding Test

Cleaning and Gas shielding are 2 very important parts of the welding process when welding titanium.

In some ways titanium is just as easy to weld as stainless steel provided proper gas shielding and cleaning is done.

But a titanium puddle can be very sticky.

The filler metal tends to stick to the base metal right near the fusion line.

That requires special wire feeding techniques.