Aluminum Lap Joint on a Cube Project

- HOME

- TIG WELDING ALUMINUM

- How to Tig Aluminum

- Aluminum Lap Joint

see more videos on TIG welding Aluminum

Video Shows 7 Tips for TIG Welding Aluminum

...Introducing the New WeldMonger Challenger TIG kit that includes the most frequently used Cups.

Here are some Tips for an Aluminum lap joint...

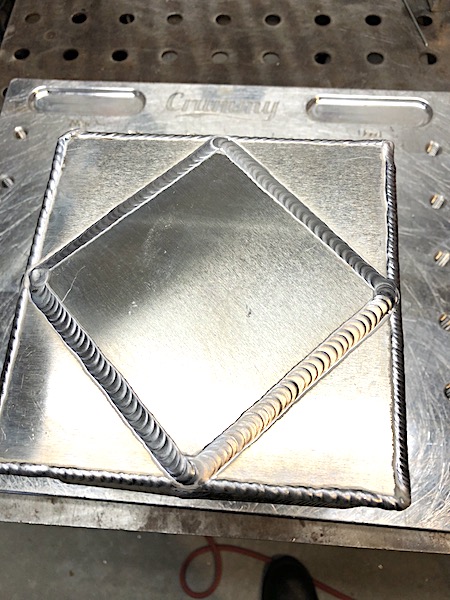

I am trying to get the most practice out of this 11 ga 6061 aluminum cube project so I decided to weld some lap joints after the cube was finished. (see the full video on aluminum cube project with outside corners)

My settings and details for these aluminum lap joints are:

120-135 amps AC soft square waveform

AC balance 67%

AC frequency 100hz

Argon set to 20cfh for the furick #8 pro cup and 15 for ally #5 cup

3/32" (2.4mm) 2% lanthanated electrode

3/32" (2.4mm) 4043 filler metal (1/16" (1.6mm) filler metal for tack welds)

There are several good choices when it comes to tig cups for an aluminum lap joint.

I know folks that use a #6 #8 or #10 gas lens along with a 1/8" or even a 5/32" electrode on 1/4" tread plate.

And I also know quite a few welders that prefer a #5 standard collet body cup for tig welding aluminum up to 3/16" thick using a 3/32" tungsten.

In the first video on this page, I used both the #8 furick cup with a gas lens and also a standard collet body ally #5 cup.

The #8 clear cup (Furick #8 pro) is a great all around cup for both DC and AC.

I use it quite a bit for aluminum and it worked great on the outside corners of this aluminum cube project.

Furick Ally #5 clear cup

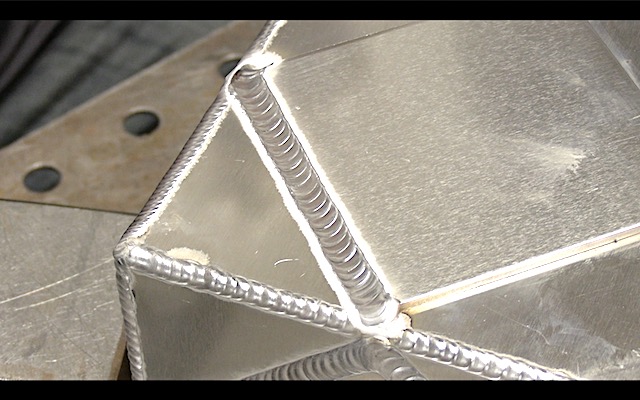

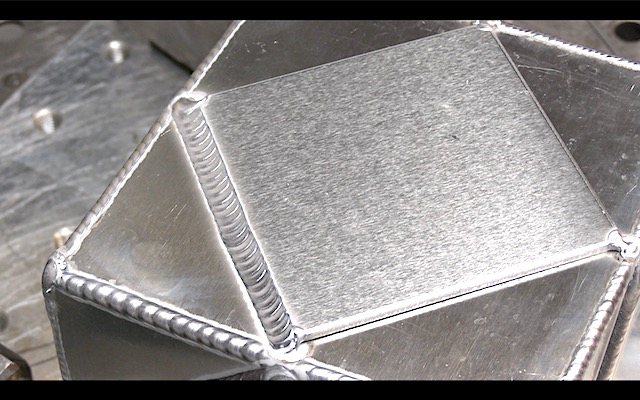

While the #8 cup worked great on the outside corner welds, i decided to compare the #8 clear cup with a ally #5 clear cup

The main difference was the etch line. also known as the cleaning zone or cathodic etch zone.

The cleaning action of the AC arc only goes as far and the argon shielding envelope.

Notice the difference these two aluminum lap joint welds where the only difference is the cup used.

Furick 8 pro Etch zone

Ally #5 etch zone

If you like a #5 standard cup for tig welding aluminum, I think you will really enjoy using the Furick Ally #5 clear cup.

It does well anywhere from 12 to 18 on argon flow and limits how wide the etch zone reaches past the toe of the weld.

Not that having a wide etch zone is a bad thing...sometimes it helps in maintaining a clean puddle on castings and such.

But for nice clean aluminum sheet up to 1/8" thick, the #5 cup definitely works great.

There is a great thread about tig cups for aluminum on my forum

So if some welders are getting great results with a gas lens setup and others are getting great results with a standard collet body, then maybe its just a matter of personal preference.