Simple Welding Metallurgy for TIg Welding 300 series Stainless Steels

- HOME

- Tig Welding Stainless

- Tig Welding Stainless Steel

- Simple Welding Metallurgy

scroll down for videos on how to TIG weld Stainless

The Two main Challenges with TIG welding stainless steel are

1. maintaining stainless properties

2. controlling distortion

Watch the latest welding videos at Weldmonger.com

If you can already TIG weld carbon steel...

Good News...

learning how to weld stainless can be a pretty easy transition.

TIG welding stainless boils down to recognizing and following a few extra steps and best practices in order to maintain the stainless properties

- HOME

- Tig Welding Stainless

- Tig Welding Stainless Steel

- Simple Welding Metallurgy

If you are still using the standard TIG cups and hardware that came with your machine or TIG torch, I can just about guarantee you will get better results if you upgrade to a weldmonger® stubby gas lens kit.

How to Weld Stainless Sanitary tubing

What Makes Stainless Steel “Stainless”?

The 300 series of stainless steels—like 304, 316, and 321—are among the most commonly used stainless materials in fabrication, food service, medical, and chemical applications.

But while they’re known for their corrosion resistance and weldability, poor welding practices can ruin those benefits fast.

This article breaks down the essential metallurgy behind 300 series stainless and how to maintain its key properties before, during, and after welding.

See detailed articles on:

🧪 What Makes 300 Series Stainless Special?

300 series stainless steels are austenitic.

That means:

- They are mostly non-magnetic ( unless cold worked)

- They have excellent corrosion resistance

- They do not harden with heat treatment

- They stay ductile even at low temperatures

These alloys get their corrosion resistance mainly from chromium and nickel—chromium forms a thin oxide layer that protects the metal, and nickel stabilizes the austenitic structure.

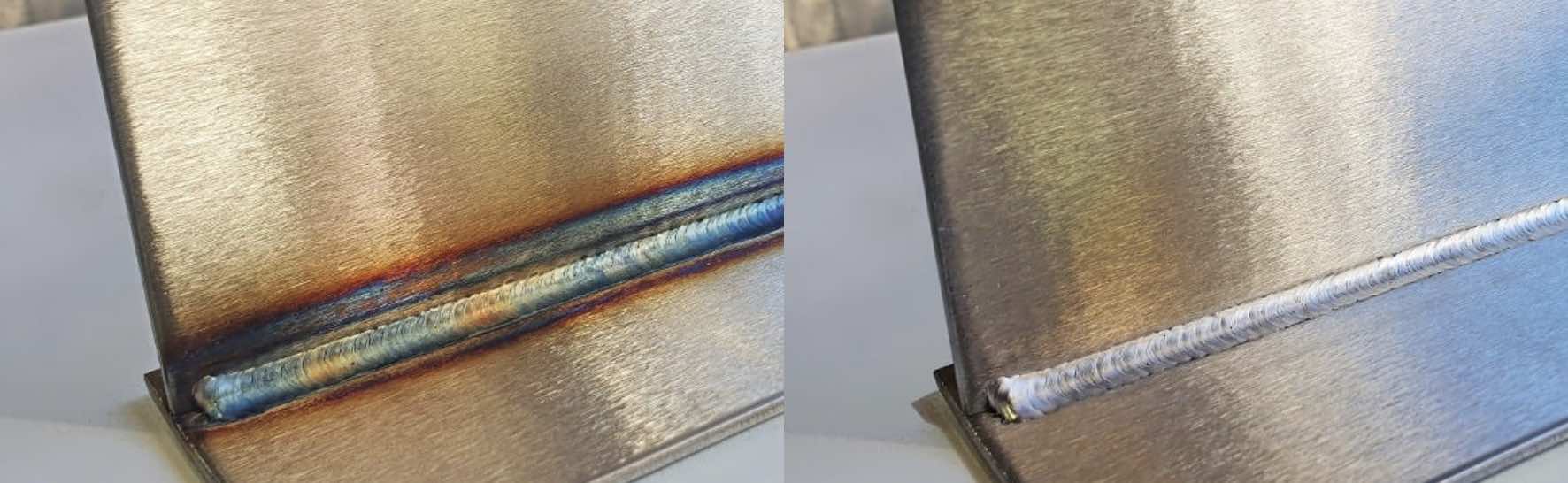

⚠️ The Welding Risk: Losing Corrosion Resistance

When welding, the main concern isn’t always strength—it’s maintaining the stainless properties, especially corrosion resistance. Improper welding can lead to:

- Carbide precipitation (chromium gets tied up with carbon at grain boundaries)

- Sugaring or oxidation on the root side of the weld

- Contamination from carbon steel tooling or poor filler choices

If you destroy the chromium oxide layer—or deplete the chromium near the weld—you turn “stainless” into just another rust-prone metal.

❄️ Why 300 Series Doesn’t Harden from Fast Cooling

Unlike carbon steel, which can form hard and brittle microstructures like martensite when cooled quickly, 300 series stainless is stable austenite. This means:

- Rapid cooling won’t harden it

- You don’t have to worry about quench cracking

- You can weld and air-cool without losing ductility

This also means that preheating isn’t necessary—even on thick sections.

Why Preheat Is Not Needed for Thick Stainless

Preheating is typically used on carbon steels to:

- Slow cooling and avoid cracking

- Reduce residual stress

- Prevent hydrogen-induced issues

But with 300 series stainless:

- There’s is very low hydrogen cracking risk

- Hardening from quick cooling is not a concern

- The alloy remains ductile even when welded cold

So unless you're welding in extremely cold environments (or onto a massive heat sink), preheat is unnecessary—and in fact, too much heat input can cause grain growth.

✨ Electropolishing After Welding: The Secret Weapon

Welding—even with good shielding—can burn off the protective chromium oxide layer and leave behind heat tint, discoloration, and roughness. This makes the weld area:

- More prone to corrosion

- Rougher and harder to clean

- A potential failure point in sanitary or chemical applications

Electropolishing is a process that removes a thin layer from the surface using an electrochemical bath.

It does three key things:

- Smooths the surface microscopically, reducing crevices for corrosion or bacteria

- Restores the passive chromium oxide layer, improving corrosion resistance

- Improves appearance, making welds blend seamlessly

➡️ Bonus: Electropolishing reaches areas that brushing or pickling might miss

Welding 300 series stainless steel isn’t hard—but preserving its properties takes discipline. To sum it up:

- Use low heat input and tight arc control

- Avoid contamination from carbon steel or dirty filler

- Skip the preheat—even on thick material

- Follow up with electropolishing or proper post-weld cleaning to restore corrosion resistance

Do it right, and your weld won’t just hold—it will stay stainless.